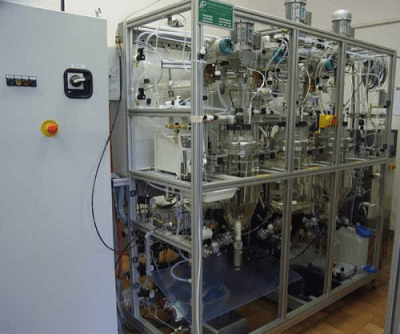

AP-Miniplant designs and manufactures customized reactors as integral components of laboratory plants and pilot plants. Our reactor systems are used across a wide range of process development tasks, supporting experimental research, process optimization, and scale-up from laboratory to pilot scale. As an experienced reactor manufacturer, we combine process engineering expertise with practical plant design to deliver reliable solutions for continuous and batch processes.

Our portfolio reflects a broad spectrum of implemented reactor concepts, developed in close collaboration with research institutions and industrial partners. The focus is on technically sound, application-specific solutions rather than standardized products.

If you are looking for a reactor solution for your laboratory or pilot plant, we are happy to discuss your process requirements. Please contact us for an individual query.

Fixed-bed reactors

Fixed-bed reactors are commonly used in laboratory and pilot plant environments for investigating heterogeneous catalytic reactions and solid catalyst behavior under defined flow and temperature conditions. Typical applications include catalyst screening, reaction kinetics studies, and long-term stability tests.

Examples range from oscillating bed reactors for dynamic flow investigations to catalyst test systems designed for high-melting or highly viscous media. Combined fixed-bed and fluidized-bed setups allow comparative evaluation of different reactor concepts within a single plant.

Oscillating Bed Reactor

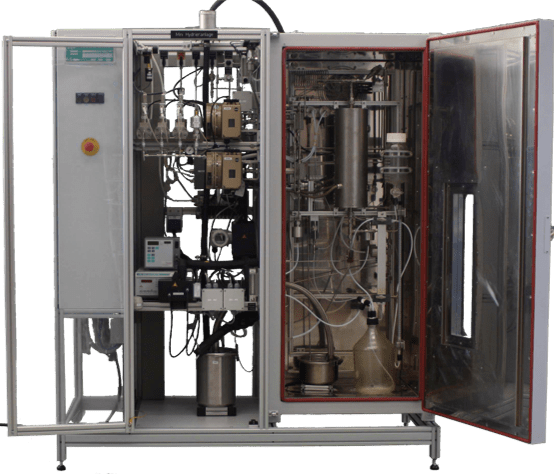

This plant consists of an oscillating bed reactor with a pulsator, offering a versatile platform…

Catalyst Test Plant for Fluids with High Melting Points

This catalyst test plant for high-melting fluids such as wax comprises a heated convection oven…

Combined Fluidized and Fixed Bed Reactor

This is a multi-purpose plant with two reactors designed for both fixed bed and fluidized…

Continuous reactors

Continuous reactors are essential for process development scenarios where steady-state operation and reproducible conditions are required. In laboratory and pilot plants, they are frequently used to evaluate process stability, residence time effects, and scalability.

Implemented systems include continuous sterilization units for food applications and containerized pilot plants for integrated process chains, such as the conversion of biogas into liquid fuels. These reactors support realistic operating conditions at pilot scale.

Mini Sterilization System for Dairy Products

This mini sterilization system for dairy products is a continuous system that has been specially…

Container Unit for Biogas to Liquid Fuel Conversion

This container unit is designed for the conversion of biogas into liquid fuel. This unit…

Combined Fluidized and Fixed Bed Reactor

This is a multi-purpose plant with two reactors designed for both fixed bed and fluidized…

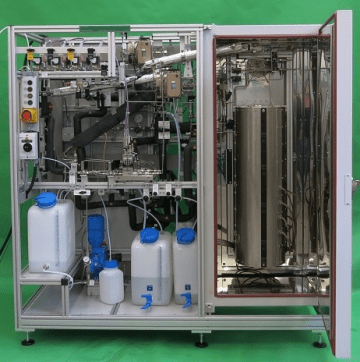

Metal-free units

For processes involving corrosive media or applications where metallic materials are unsuitable, metal-free reactor units provide a reliable alternative. Glass reactors and associated process equipment enable precise temperature control and visual process observation. High-quality, functional plastics, glass reactors, or ceramic materials are used in the reactor for this purpose.

Crystallizer with Internal Heat Exchanger

This crystallizer with internal heat exchanger provides an excellent environment for the development of crystallization…

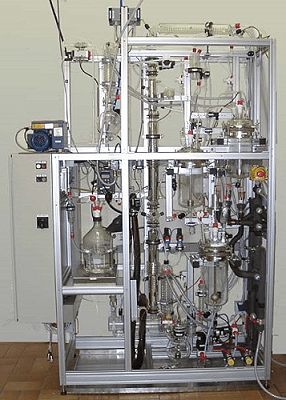

Distillation Plant with Integrated Evaporation Crystallization

This distillation plant with evaporation crystallization was specially developed to characterize distillation processes with crystallization…

Crystallization Plant Made of Glass with 4 Reactors

This crystallization plant is equipped with a total of four glass reactors, including two 10-liter…

Membrane reactors

Membrane reactors integrate chemical reaction and selective separation within a single unit. This concept is particularly relevant for equilibrium-limited reactions and selective gas-phase processes.

AP-Miniplant has realized membrane reactor systems for high-temperature and high-pressure applications, as well as test units with integrated analytical equipment such as gas chromatographs. Extended reactor lengths allow investigation of axial process behavior and scale-up effects.

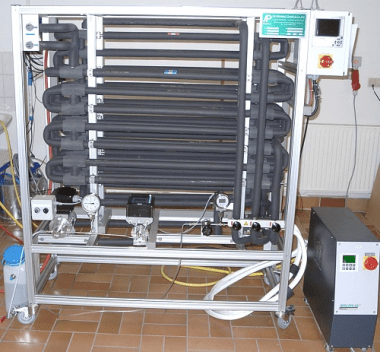

Membrane Reactor Test System for Reactors up to 1100 mm

This membrane reactor test system has been prepared for customer reactor installation. It allows installation…

Membrane Reactor Test System with integrated Gas Chromatograph

This membrane reactor test system, prepared for customer reactor installation, offers customized solutions for research…

Membrane Reactor Test System up to 63 bar and 900 °C

This system, prepared for the installation of a membrane reactor by the customer, is the…

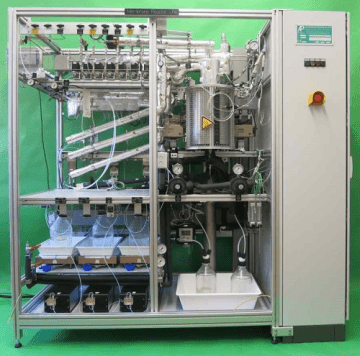

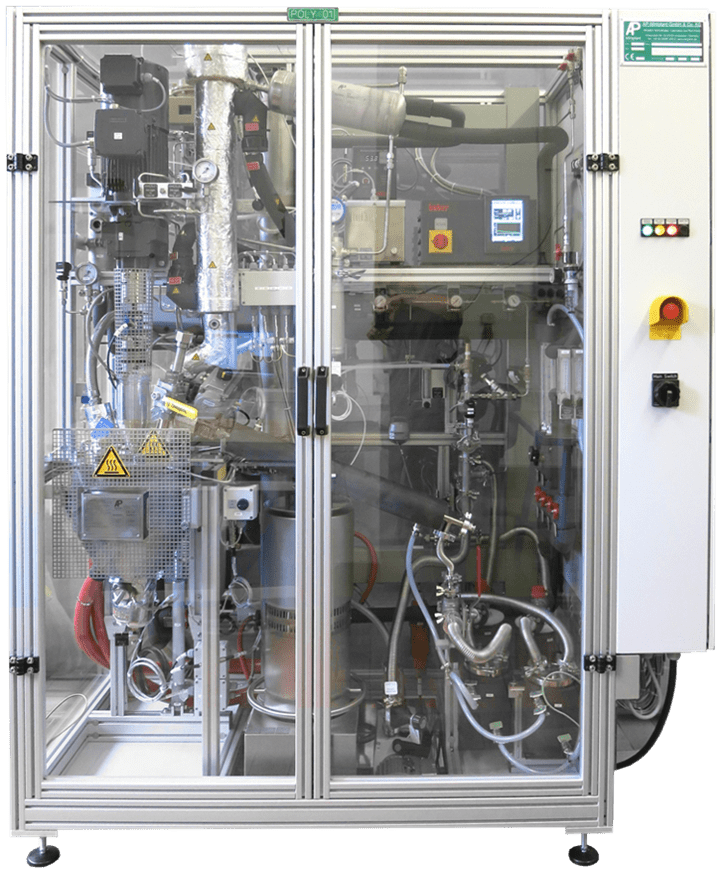

Polymerisation reactors

Polymerization reactors are designed to support controlled synthesis under defined thermal and pressure conditions. In laboratory and pilot plants, these systems are used to study reaction kinetics, material properties, and process stability.

AP-Miniplant has extensive expertise in the planning, construction, and automation of polymerization plants. We pay particular attention to process-critical equipment and sub-processes such as pump technology, agitators, and temperature control.

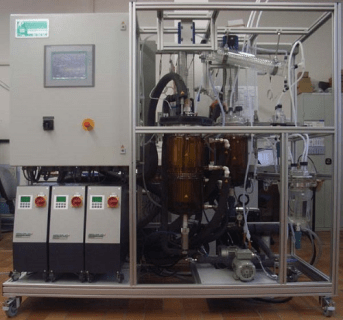

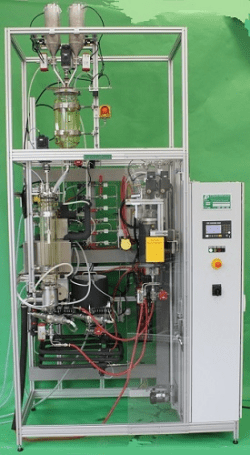

Stirred Pressure Reactor for Polymerization

We have developed this polymerization reactor system with a compact design so that it is…

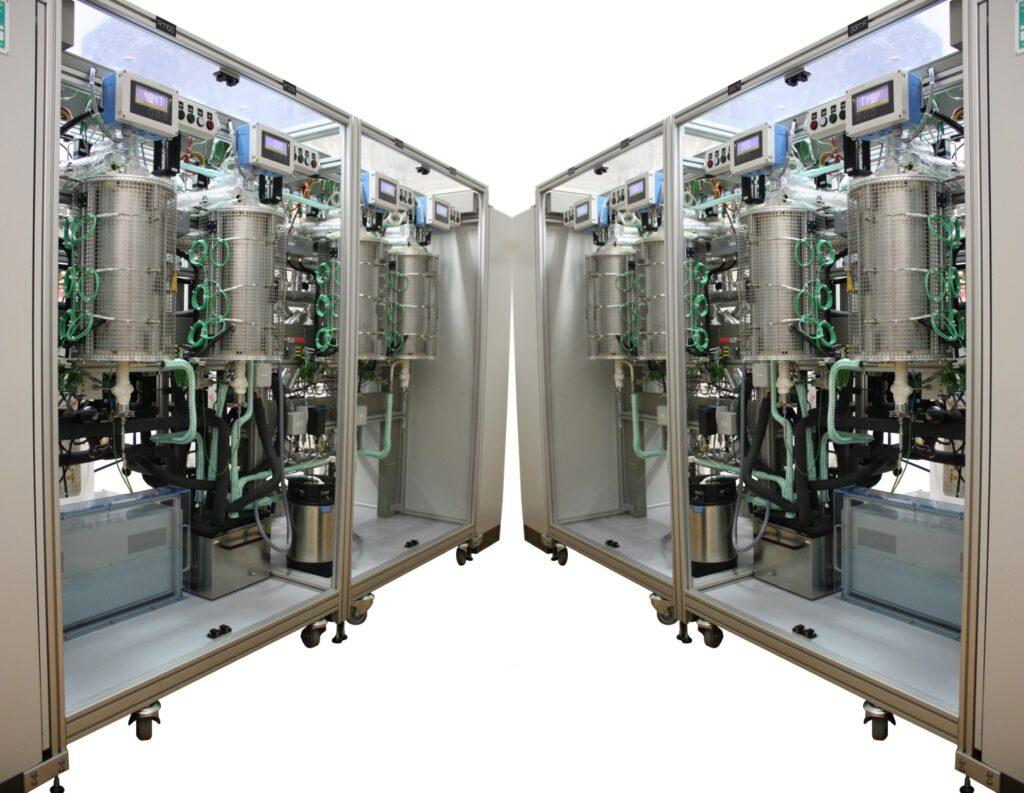

2-Stage Melt Polymerization Plant

This 2-stage melt polymerization plant is designed for high-temperature polymerization processes. It consists of two…

10 L Polycondensation Plant

This 10-liter polycondensation plant includes a compact 10-liter stainless steel reactor. The entire system is…

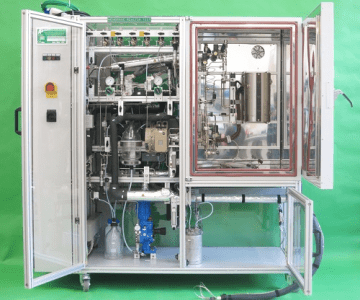

Reactive distillation

Fully automated, continuous laboratory systems are particularly suitable for testing complex, functionally integrated processes. A classic example of this is reactive distillation, which is often used in equilibrium-limited reactions to improve yield and has been implemented by us in various systems.

Reactive Distillation Plant up to 32 bar and 350 °C

This reactive distillation plant is designed for chemical reactions in combination with distillation processes under…

4 L Melt-Polycondensation Reactor

This system includes a 4-litre polycondensation reactor as the main reactor. The optimum amount of…

Stirred reactors

Stirred reactors represent a versatile reactor type for laboratory and pilot plant applications. They can be configured for batch or continuous operation and adapted to a wide range of chemical processes.

Depending on the application, these systems may include automated dosing, advanced process control, and integrated analytical instrumentation, making them suitable for both research and pilot-scale operation.

Fully Automated Micro Brewery

This fully automated micro-brewery is the perfect solution for fast and reproducible product development in…

Distillation Plant with Integrated Evaporation Crystallization

This distillation plant with evaporation crystallization was specially developed to characterize distillation processes with crystallization…

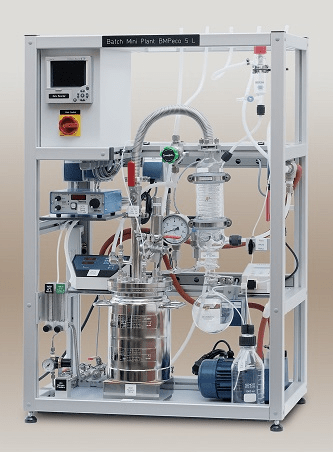

Cost-Effective Batch System with 5 L Reactor Volume

This cost-effective batch plant with a capacity of 5 liters is a compact and budget-friendly…

Tube oven

Tubular reactors are typically applied in gas-phase processes, catalytic reactions, and high-temperature studies. Their design allows precise control of residence time, heat transfer, and reaction atmosphere.

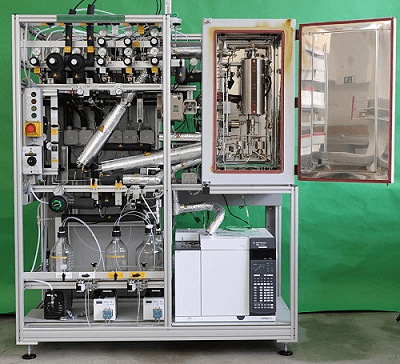

Micro Reactor System with GC

This micro reactor system offers an impressive range of functions for research and process development…

Catalyst Test System for SCR-catalysts

This Catalyst test system for SCR-catalysts has been developed for the automated test of monolytic…

Catalyst Test Plant for Fluids with High Melting Points

This catalyst test plant for high-melting fluids such as wax comprises a heated convection oven…

Fluidized bed reactors

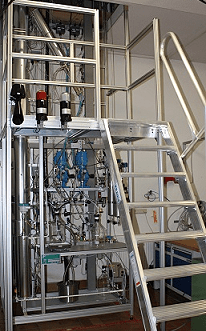

Test Plant for Fluidized Bed Reactor Research

This fluidized bed reactor test system is a versatile system designed for research and testing…

Simple Fluidized Bed Reactor for Catalyst Activation

This simple fluidized bed reactor is using a specialized tubular quartz glass reactor with a…

Combined Fluidized and Fixed Bed Reactor

This is a multi-purpose plant with two reactors designed for both fixed bed and fluidized…

Special reactors

Often, a process requires its own reactor solution. Together with our customers, we also develop customized reactor and plant solutions for such processes.

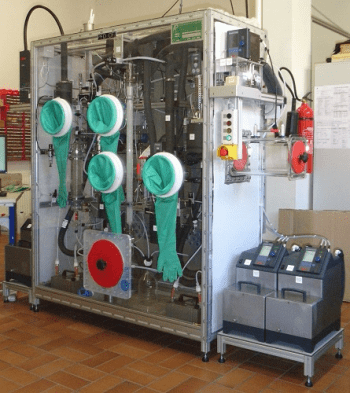

Hermetically Sealed Plant with Airlock and Wash Column

Hermetically sealed stirred tank equipment is the ideal solution for the safe handling and processing…

Gas Phase Polymerization Plant

This gas phase polymerization plant uses a 1.8 liter reactor designed to operate at 175…