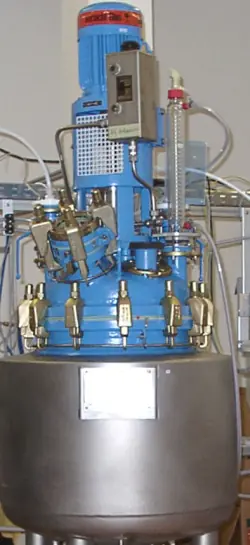

This crystallization plant is equipped with a total of four glass reactors, including two 10-liter reactors and two 5-liter reactors. It provides a precise and versatile platform for crystallization processes. This plant allows operation in vacuum up to 1.5 bar abs. as well as temperatures ranging from -40 to 130 °C .

It includes condensers, pumps, coolers, and an inerting and venting system. Full automation through Siemens S7, Simatic WinCC and recipe control ensures precise and reliable crystallization processes for many days and weeks.

Features:

- Four glass reactors for crystallization processes.

- Sizes: 2 x 10 L and 2 x 5 L.

- Control of vacuum and temperatures (-40 to 130 °C).

- Includes condensers, transfer pumps, coolers and venting system.

- Fully automated control with Siemens S7 and Simatic WinCC.

- Recipe control for precise process control.