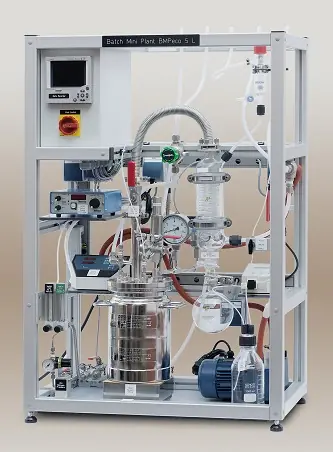

This cost-effective batch plant with a capacity of 5 liters is a compact and budget-friendly solution for reaction and stirring tasks for homogenous low viscosity liquids. The operating pressure is -1 to 4.5 bar and a maximum temperature is 150 °C, the stirred reactor features a guided magnetic stirrer propelled from below the vessel. With a double jacket for heating and cooling, a dip tube for draining and manually adjustable speed control on the controller, this unit is ideal for simple batch processes. In addition, a distillation bridge, vacuum pump with vacuum regulator, and nitrogen gassing are included. This low cost batch reactor is controlled via individual controllers, while a screen recorder with USB interface allows for data logging.

If you find this system interesting, take a look at our range of laboratory reactors and laboratory reactor systems.

Features:

- Cost-effective 5 l batch system for laboratory applications.

- Stirring reactor with -1/6 bar design pressure (operating ~4.5 bar) and 150 °C temperature.

- Contactless magnetic stirrer drive from below.

- Double jacket for heating and cooling.

- Manual speed adjustment on control unit.

- Contains distillation bridge, vacuum pump, and nitrogen gassing system.

- Automation with individual controllers and data logging via USB interface.