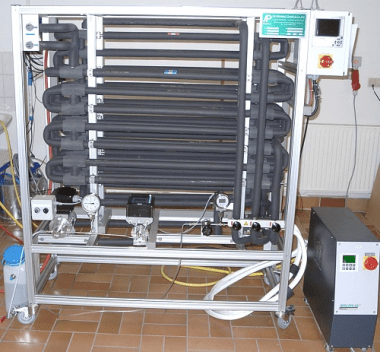

This mini sterilization system for dairy products is a continuous system that has been specially developed for the sterilization of medium-viscosity liquids such as milk or yoghurt. It offers a reliable test system for checking sterilization processes. It can also be used to characterize fouling processes and validate cleaning procedures. With a variable speed gear pump offering a maximum capacity of 26 liters per hour, combined with a mechanical pressure regulator, flow meters and three heat exchangers for heating and holding, plus one for cooling, this unit is fully functional for measuring and testing sterilization processes. The heat exchangers are designed as double-jacketed tubes, The U-Connectors can be dismantled for manual cleaning, if cleaning with hot water/steam is not sufficient. Control is via individual controllers and a datalogger records important data.

Features:

- Continuous sterilization system for dairy products.

- Speed-controlled gear pump (max. 26 l/h).

- Three heat exchangers for heating and holding, one heat exchanger for cooling.

- Double jacket tubes for easy cleaning and maintenance.

- Precise control with individual controllers and data recorder.