As a manufacturer of custom-engineered plants and process equipment, our solutions are always tailored to the specific application. From compact containerized systems and dedicated test stands for catalysts and electrochemical processes to cost-effective training plants for education and teaching, we provide practical, application-oriented systems with reliable automation and customized configurations.

Below, we present a selection of different plants, each representing a distinct functional unit. Please feel free to contact us if you have questions about any of the units shown or if you would like to request a quotation.

Fuel cell test stands

Dedicated test stands for evaluating fuel cell systems and components such as jet pumps or modular fuel cell units.

These systems enable reproducible performance and operating parameter analyses under realistic operating conditions.

Modular Test Bench for Fuel Cell Systems with 100 kW

Our modular test bench for fuel cell systems, with an impressive output of 100 kW,…

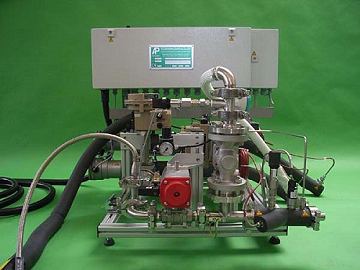

Jet Pump Test Unit for Fuel Cell Systems

Our jet pump test device for fuel cell systems is designed to test jet pumps….

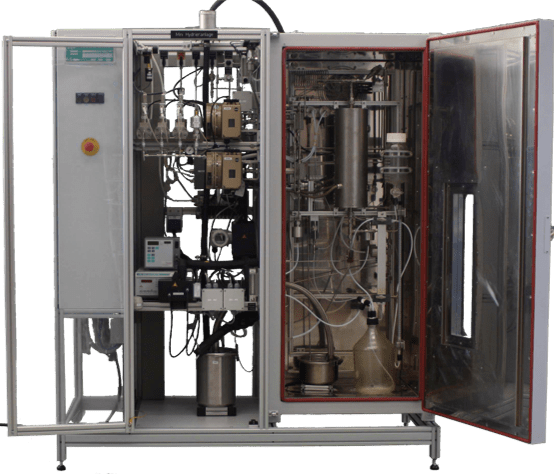

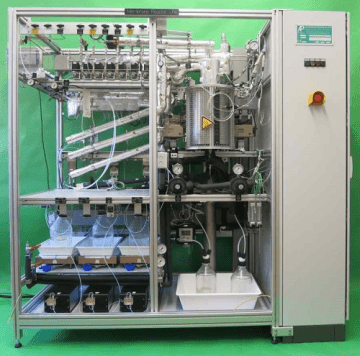

Catalyst test systems

Test plants for the evaluation and development of catalytic systems, such as SCR catalysts or high-melting fluids.

The test systems offer parallel testing capabilities and precise process control for research and optimization. In addition to providing process equipment designed for high pressures and temperatures, AP-Miniplant delivers reliable plant automation suitable for long-term testing campaigns.

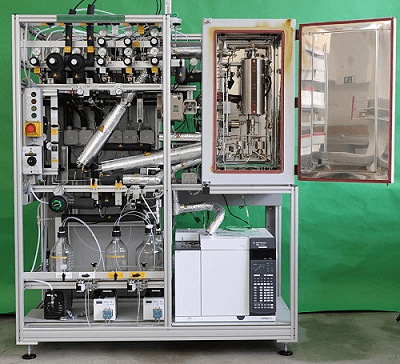

Micro Reactor System with GC

This micro reactor system offers an impressive range of functions for research and process development…

Catalyst Test System for SCR-catalysts

This Catalyst test system for SCR-catalysts has been developed for the automated test of monolytic…

Catalyst Test Plant for Fluids with High Melting Points

This catalyst test plant for high-melting fluids such as wax comprises a heated convection oven…

Dosing systems

Process systems capable of accurately dosing even the smallest quantities of solid, liquid, or gaseous media are essential in research and development for evaluating and scaling up overall processes.

AP-Miniplant develops not only robust automation concepts but also innovative dosing technologies for low and continuous material flow rates.

Fully Automated Micro Brewery

This fully automated micro-brewery is the perfect solution for fast and reproducible product development in…

Micro Reactor System with GC

This micro reactor system offers an impressive range of functions for research and process development…

Catalyst Test System for SCR-catalysts

This Catalyst test system for SCR-catalysts has been developed for the automated test of monolytic…

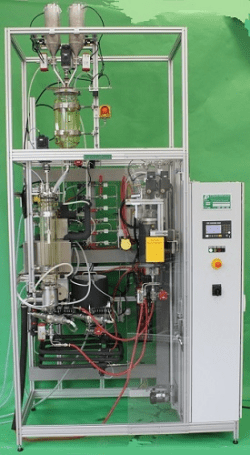

Electrosynthesis Test Systems

Electrosynthesis test stands for the development and investigation of electrochemical reactor concepts.

They offer flexible configurations for series or parallel operation and support the optimization of electrochemical processes. Both current and voltage can be controlled and implemented via recipe-based operation.

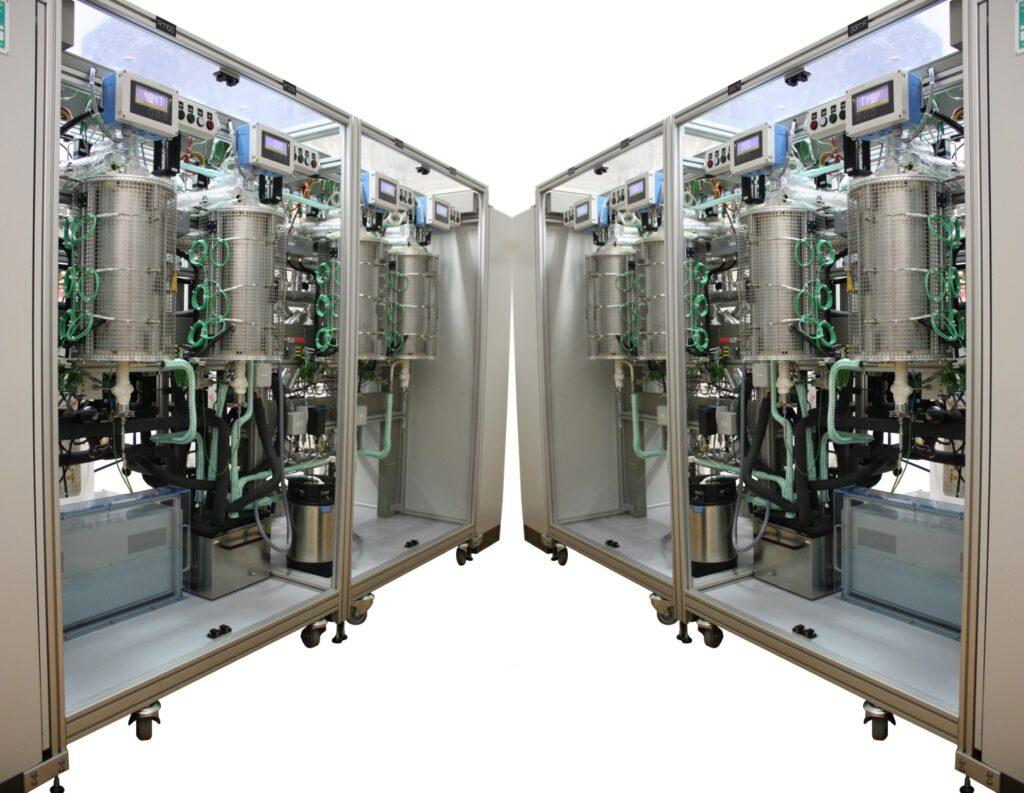

Electrosynthesis Test Stand for the Development of Reactors

The basic configuration of our electrosynthesis test stand offers the flexibility of parallel or series…

Gas Conditioning

Systems for gas preparation, handling, and analysis, including integrated measurement and testing components such as gas chromatographs.

These plants are suitable for research and process development in a wide range of chemical and process engineering applications.

Membrane Reactor Test System with integrated Gas Chromatograph

This membrane reactor test system, prepared for customer reactor installation, offers customized solutions for research…

Catalyst Test System for SCR-catalysts

This Catalyst test system for SCR-catalysts has been developed for the automated test of monolytic…

Gas Phase Polymerization Plant

This gas phase polymerization plant uses a 1.8 liter reactor designed to operate at 175…

Recycling Systems

Practical, application-ready plants for material recovery and energy utilization.

Examples include multi-stage evaporators, metal-free systems for aggressive media, polymer recycling plants, and containerized systems for converting biogas into fuel.

Multi-Stage Evaporation Plant with Heat Integration

This multi-stage evaporation plant with a two-stage evaporation system and a capacity of 10 liters…

Metal-free Plant for the Recovery of Solids and Aggressive Acid

This metal-free recycling plant is suitable for the recovery of solids containing extremely aggressive inorganic…

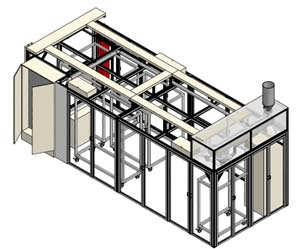

Container Unit for Biogas to Liquid Fuel Conversion

This container unit is designed for the conversion of biogas into liquid fuel. This unit…

Training & Educational Systems

Didactically optimized systems for education, teaching, and professional training in process engineering.

These systems represent typical technical tasks, such as stirred tank and tubular reactor training units or gas pressure reduction stations.

Multi-Stage Evaporation Plant with Heat Integration

This multi-stage evaporation plant with a two-stage evaporation system and a capacity of 10 liters…

Training Plant with 3 Stirred Tanks and Tubular Reactor

Our training plant with 3 stirred tanks and a tubular reactor has been specially developed…

Training Plant for Fuel Gas Pressure Reduction

Our Fuel Gas Pressure Reduction Training Plant was specially developed for training and education purposes….