The stirrer couplings described here perform two tasks: The secure sealing of the rotating union under vacuum and pressure and the reliable and long-lasting bearing of the shaft. The main areas of application are agitator vessels for mixing processes, reactions and the homogenization of liquids in chemical production.

We offer you particularly space-saving yet powerful stirrer couplings, which make it easier for you to implement additional process connections in your laboratory reactor. By combining our stirrer couplings with our frequency and torque sensors, you can optionally monitor the power input precisely.

Magnetic stirrer couplings

Our magnetic stirrer couplings are characterized by their robust design and particularly maintenance-friendly construction.

In the upper area, two ceramic ball bearings guide the shaft without lubrication. Towards the process, a plain bearing prevents the ingress of dirt and provides additional guidance for the shaft. The seal can be flushed with nitrogen to make it more difficult for process gas to penetrate the seal. In addition, nitrogen gassing can reduce the load on the coupling chamber caused by process gas. The nitrogen then flows through the plain bearing into the container. The agitator with a shaft diameter of Ø16 mm is screwed into the shaft of the seal. A steel shaft can also be inserted from the outside after opening two plugs to make it easier to block the shaft when the agitator is jammed for release.

The agitator couplings are characterized by their robust performance features. They can withstand a maximum pressure of 60 bar and are designed for a temperature range of -40 to 250 °C without cooling. With a flexible speed of 0 to 2000 rpm, they offer a wide range of applications. The maximum transmission force is 8 Nm. We would be happy to offer you a customized system for your requirements.

The design with the slimmest possible lower part is particularly suitable for smaller reactors. This makes it easier to connect smaller pipes relatively close to the seal. The stirrer coupling is connected to a reactor cover with a G 1″ thread.

A hole in the shaft also allows direct connection to our torque sensor. A cardan or other coupling can also be connected to the outer diameter on the motor side.

Mechanical seals

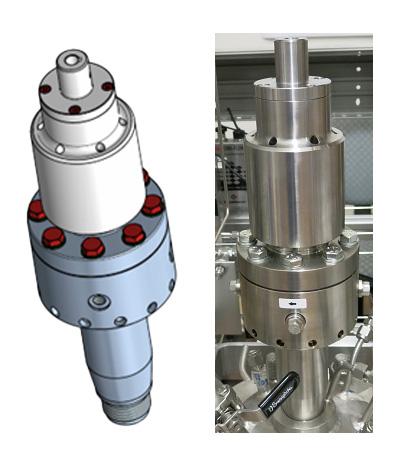

Our double-acting mechanical seal is primarily used in processes where process gas precipitates as a solid in the gas phase or where the gas phase would place a heavy load on the bearings of a magnetic agitator coupling. As there are no bearings in the product chamber with this type of seal, agitator couplings of this design are particularly durable under these demanding process conditions.

AP-Miniplant exclusively offers a mechanical seal specially tailored to small container diameters. The conical shape at the bottom makes it possible to accommodate small pipe connections close to the agitator coupling.

The mechanical seal is available for agitator shafts with a diameter of Ø16 and Ø25 mm. The maximum process conditions are a pressure of 50 bar and temperatures of up to 340 °C. Due to its compact design, it requires a forced circulation barrier fluid circuit. The pressure and temperature of this barrier circuit is regulated in automated AP miniplant systems. A gear pump ensures the circulation. The pressure control allows the sealing pressure to be adjusted relative to the process pressure. This keeps wear to a minimum, as only as much overpressure is exerted on the seal as is required to maintain tightness. Temperature control is particularly important if there is a risk of unwanted condensation in the connection area of the seal. In such cases, the sealing circuit can be operated at higher temperatures of max. 140 °C.

Lip seal

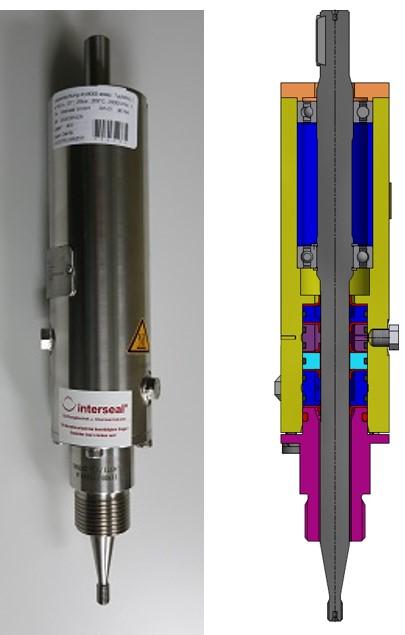

The DrySeal lip seal is intended as a cost-effective alternative to the mechanical seal. Compared to the latter, it is considerably slimmer and does not require a sealing circuit. This type is manufactured exclusively for us by Interseal using the DRY 9000 sealing principle. Its slim design makes it particularly suitable for small systems. Sealing is achieved with PTFE sealing lips in both directions, so that the coupling can be used both at pressures of up to 25 bar and in a vacuum.

The agitator shaft is a 16 mm stainless steel shaft with a 20° internal cone and an 8 mm internal thread. The maximum operating temperature without cooling is 200 °C. A cooling sleeve is available. The screw-in thread is G1″ external.

The coupling is equipped with a connection for the flushing medium after the first seal and a connection for monitoring the tightness of the penultimate seal, both viewed from the process. A temperature sensor can be inserted into a prepared hole to monitor the temperature of the seal. The motor can be connected at the journal end with a size 16h6 feather key.