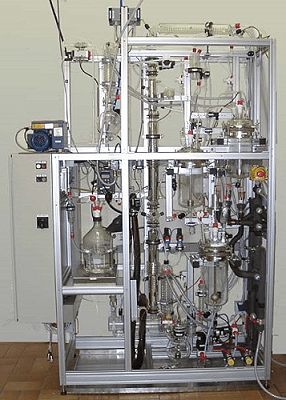

This is a multi-purpose plant with two reactors designed for both fixed bed and fluidized bed operation. Each reactor has a multi-zone furnace for precise temperature control and maximum process control.

This unit offers a high degree of flexibility with 12 gas dosing options and 2 liquid dosing options. An integrated gas phase chromatograph (GC) allows gas analysis at different points, so you can always monitor reactant and product quality. An additional evaporator for ultrapure water means that a wide range of processing requirements can be met. The system therefore is multifunctional and can be used for a variety of different processes.

For comprehensive control of the multi-purpose plant, it is not only fully automated, but also has an innovative recipe control system that can be used to optimize process control. The use of an industrial control system ensures maximum reliability.

Features:

- Multi Purpose Plant.

- 2 reactors tubular/fluidized bed with multi-zone furnace.

- 12 Dosings of gas / 2 dosings of liquid.

- Gas-phase chromatograph (GC) / evaporator.

- Fully automated with industrial control system.

Technical Specifications

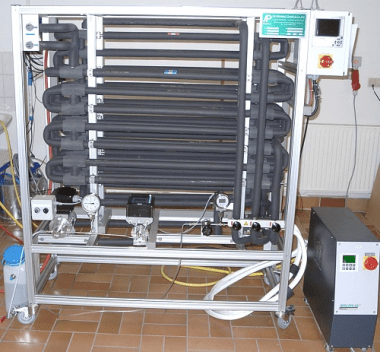

| Description | Unit | Value |

|---|---|---|

| Dimensions L x W x H | mm | 2250 x 1000 x 1950 |

| Weight | kg | 750 |

| Electrical supply | 3P ~ 220 V / 60 Hz / 36 A | |

| Ambient conditions | °C | 10 to 40 |

| Tubular Reactor (High Temp. Stainless steel) | PS = 40 bar at TS = 700 °C / PS = 100 bar at TS = 400 °C, operating pressure 80 % of PS | |

| Fluidized Bed Reactor (Quartz glass) | bar | PS = 0,5 bar / TS = 1000 °C |

| Mediums | e.g. hydrogen, methane, carbon dioxide, oxygen, propane, air | |

| Other | 7-heating zones tube furnace, 3 heating zones for fluidized bed GC | |

| Cooler | kW | 2.2 |

| Automation | 24/7 control with step based recipe system |