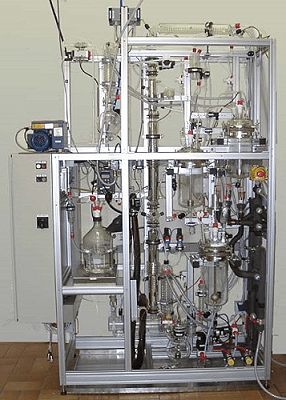

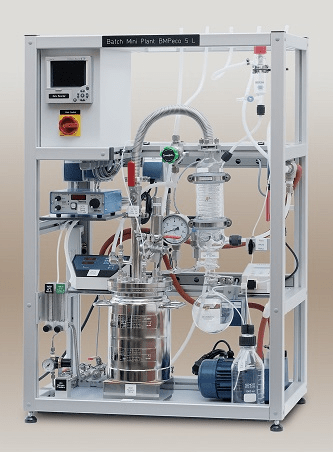

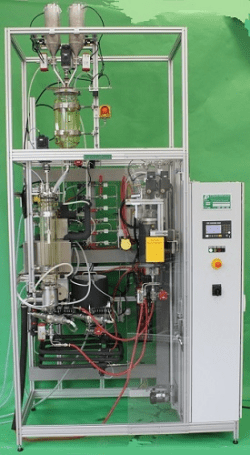

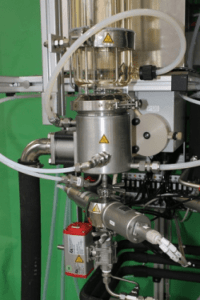

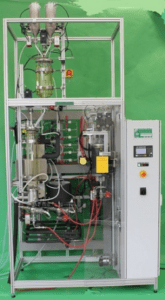

This fully automated micro-brewery is the perfect solution for fast and reproducible product development in the brewing industry. This innovative plant enables the automated production of beer in small quantities, with batch sizes of approximately 2 liters. With sophisticated equipment that includes 2 malt silos, mash tun, lauter tun with recirculation pump, optical turbidity measurement, brew kettle with automatic hop dosing and a whirlpool tank for secondary clarification and product cooling, this micro-brewery is the perfect choice for fully automated product development.

Features:

- Automated batch production of approximately 2 liters of beer.

- Integrated malt silos, mash tun and lauter tun.

- Optical turbidity measurement for precise quality control.

- Automatic hop dosing and brew pan.

- Automated cleaning with CIP nozzles and filter layer removal.