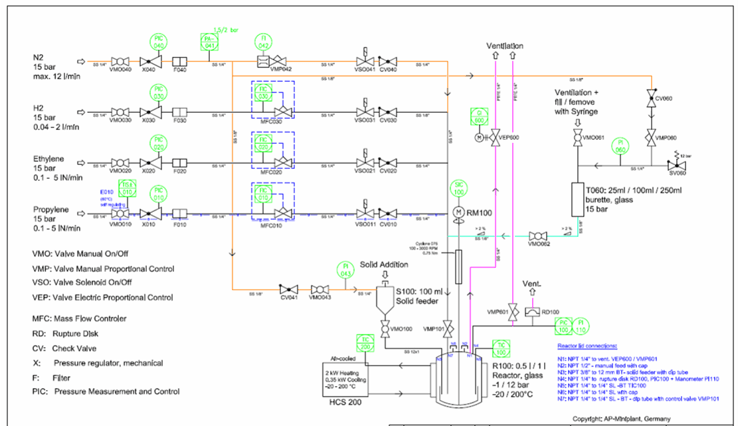

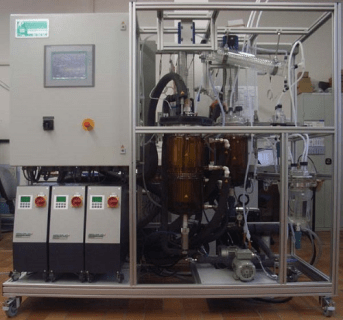

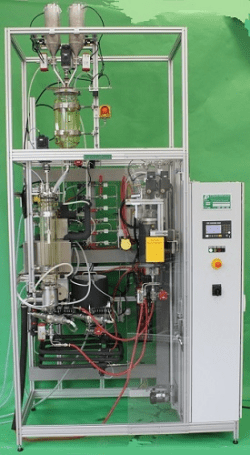

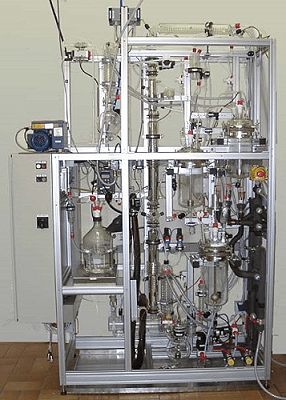

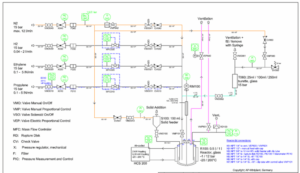

This glass polymerization plant contains exchangeable glass pressure reactors. They come in two sizes, 1 liter and 0.5 liters. The reactors feature a heating and cooling system and are equipped with three automatic gas feeds. You also have the option for manual solid and liquid feed. These reactors are controlled by a PLC – industrial control system, providing you with precise control for your experiments.

The clear and intuitive operation allows you to start polymerization quickly. Thanks to the compact, mobile design, you can use this glass polymerization plant flexibly and even operate it up to 12 bar within an autoclave room.

Description:

- Intended use: Polymerization of ethylene or propylene.

- Glass reactor 1 l with automatic pressure control.

- Controlled dosing of 3 different gas feeds (e.g. ethylene, hydrogen, and propylene).

- Liquid feed addition via burettes (maximum volume 250 ml).

- Solid feeder to add slurries and solids under pressure.

- Extendable via spare connections.

- Max. pressure 12 bar in a safe room.

- Design temperature 200 °C.

Technical Specifications:

| Description | unit | Value |

|---|---|---|

| Dimensions L x D x H | mm | 990 x 760 x 1800 |

| Weight | kg | 191 |

| Pressure in circuit | bar | -1 to 12 in an autoclave room -1 to 6 in a laboratory environment. Recommended operating pressure is 80% of the allowable pressure Reactor is suitable for vacuum applications |

| Temperature | °C | -20 to 200 °C |

| Reactor type | Buechi® Ecoclave®, 1 and ½ liter glass with jacket and round bottom | |

| Motor type | Cyclone 075 with integrated magnetic coupling | |

| Stirrer speed | rpm | 100 – 3000, limited to 1500 in automatic mode |

| Stirrer torque | Ncm | Max. 75, continuous torque 16 |

| Gas supplies | Nml/min | Propylene 100 – 5000 Ethylene 100 – 5000 Hydrogen 40 – 2000 |

| Liquid supplies | Exchangeable burettes, 25, 100 and 250 ml | |

| Solid and slurry supply | Dosing unit, 100 ml | |

| Vent control valve | Samson control valve type 3510 with electrical drive, kvs = 0.025 (m³/h) |