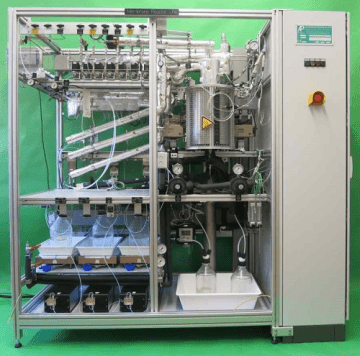

This container unit is designed for the conversion of biogas into liquid fuel. This unit is housed in a container that includes the entire plant as well as an operator station with a PC. Moreover, it is equipped for remote control operations, providing flexibility in monitoring and management.

Features:

- Biogas container unit.

- Transformation of biogas to liquid fuel.

- Container unit housing the plant and the operator station with PC.

- Remote control possible.

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 3000 x 800 x 2200 – container: 4400 x 2440 x 2800 |

| Weight | kg | 1600 / 5000 with container |

| Electrical supply | 3P ~ 400 V / 50 Hz / 50 A | |

| Biogas supply | bar | PS = 0,4 bar / TS = 60 °C |

| Reformer | °C | TS = 950 °C |

| Vessel (2x) | bar | PS = 0,5 bar / TS = 250°C and PS = 30 bar / TS = 300 °C |

| Reactor | PS = 30 bar / TS = 350 °C, category III PED | |

| Compressor | 3-stage, hermetic, electrical drive | |

| Control system | Industrial control system 24/7 with recipe control |