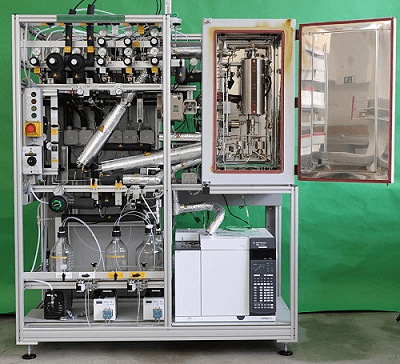

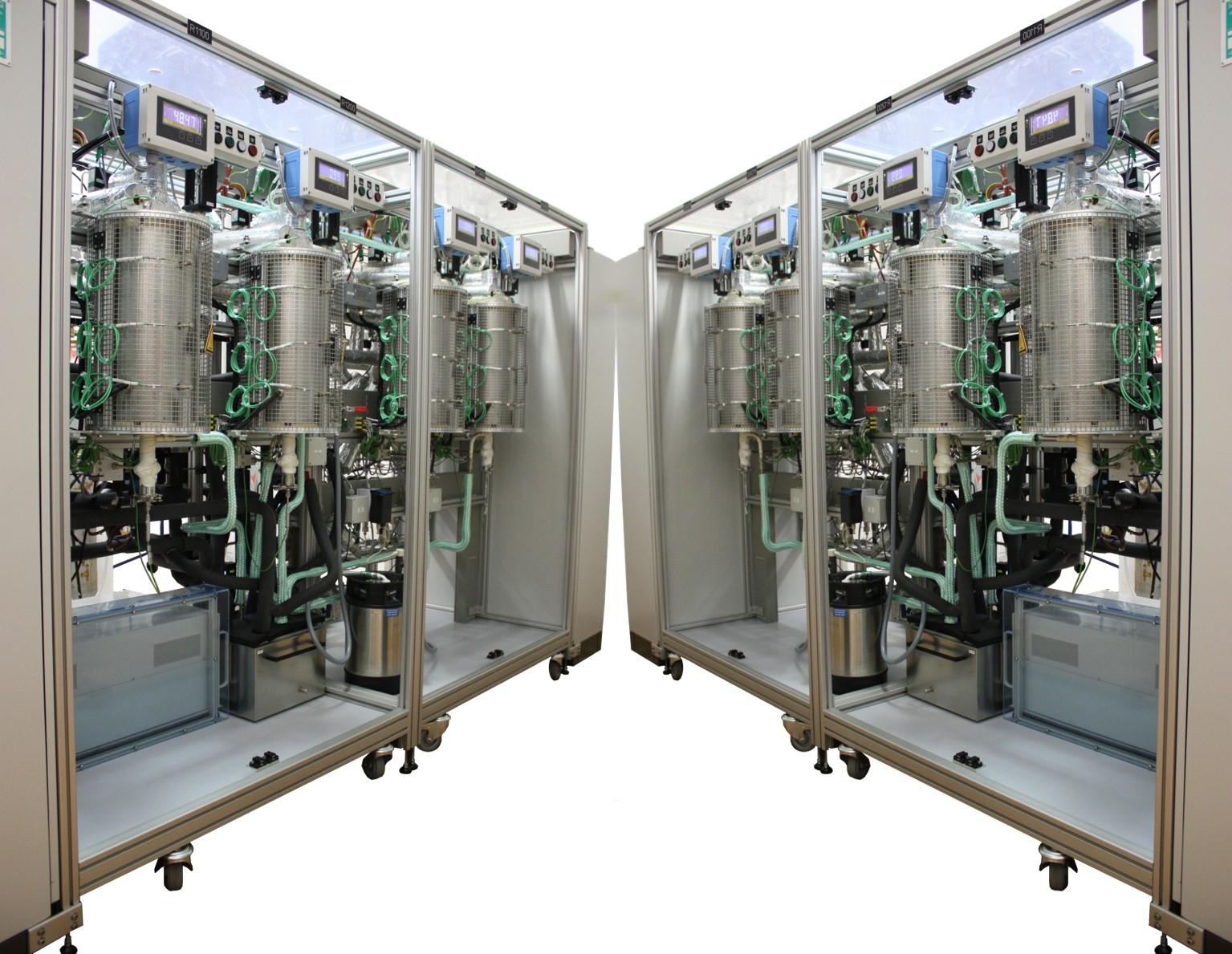

This Catalyst test system for SCR-catalysts has been developed for the automated test of monolytic catalysts, namely SCR-catalysts. The focus is on quality control during production.

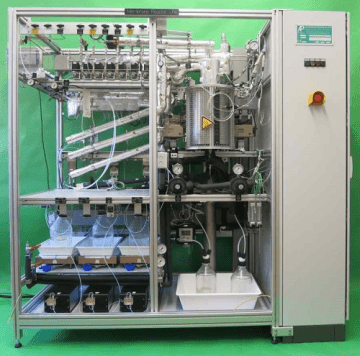

The gas supply with 10 different gases controlled by mass flow meters enables the composition to be set precisely. A defined proportion of vapor can be set via the integrated vaporizers.

The composition is checked via an FTIR and an oxygen sensor and automatically readjusted. A second gas supply enables a sudden change between 2 compositions.

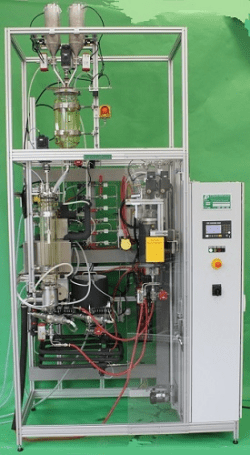

The reactor itself is made of high-temperature stainless steel with a removable inner tube made of quartz glass. The maximum temperature under pressure is 850 °C, without pressure up to 1000 °C.

The multi-reactor catalyst test system is fully automated, enabling reliable testing and continuous data collection throughout the catalyst testing process. This level of automation increases the accuracy and repeatability of the tests and makes this catalyst test system for SCR-catalysts a valuable tool for quality control, but also for catalyst research and development.

Features:

- Gas supply , e.g. for artificial exhaust gas.

- Integrated evaporators.

- Inert reactor made of Quarz glass with a pressure resistant steel shell.

- Fully automated catalyst testing.

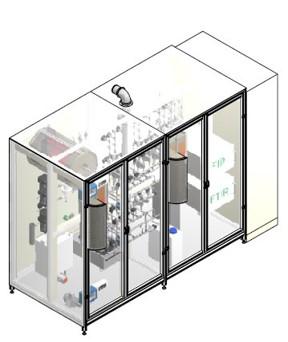

Technical specifications

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 3100 x 1200 x 2200 |

| Weight | kg | 1300 |

| Electrical supply | 400 V, 50 / 60 Hz, 50 A | |

| Ambient conditions | 10 to 35 °C, max. humidity < 80 % | |

| Pressure conditions | bar | 0 – 3 |

| Temperature conditions | °C | Reactor: 10 – 850 °C, optional up to 1000 °C |

| Reactor type | Quartz glass reactor embeded in a pressure resistant stainless steel tube (1.4841) | |

| Gas heating unit | Inline gas heater with high dynamics (T(gas)max= 640 °C) Higher temperatures on request. | |

| Analytic system | FTIR, oxygen sensor, others are possible | |

| Gas supplies | N2, O2, NOx, NH3, H2, N2O, CO, CO2, CH4, SO2 Others on request. | |

| Liquid supplies / evaporators | Dosing unit and evaporator for water and hydrocarbons. Optional: Ion exchanger cartridges for water conditioning. | |

| Exhaust gas treatment | Condenser, gas cooling and dilution |