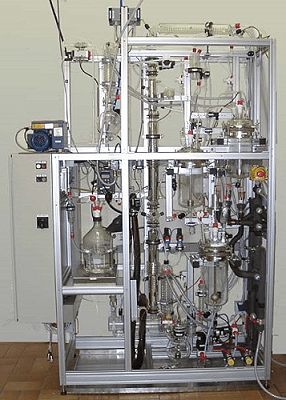

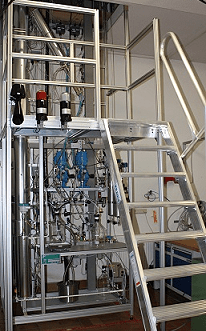

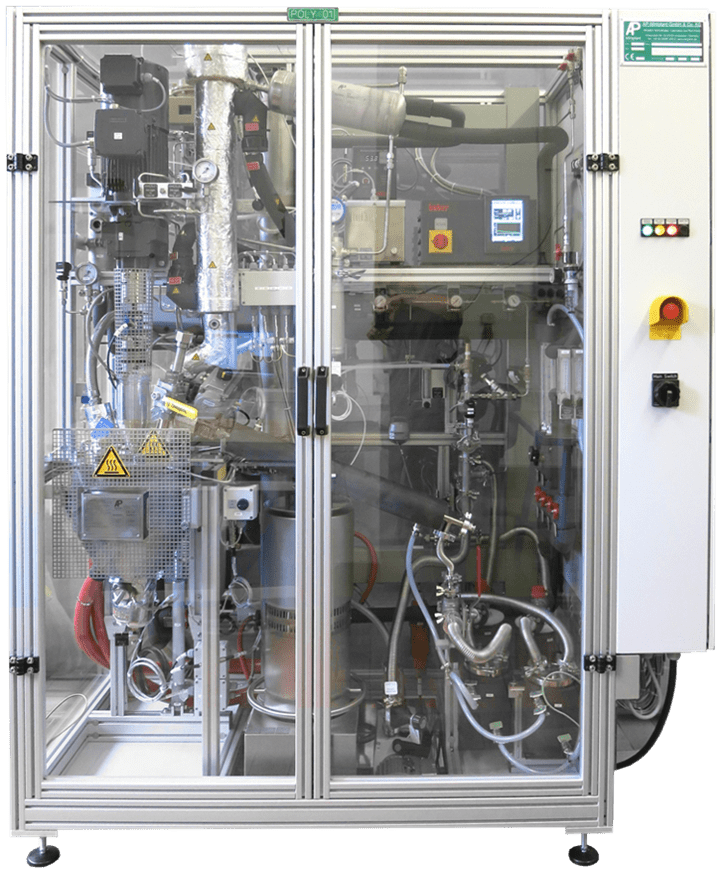

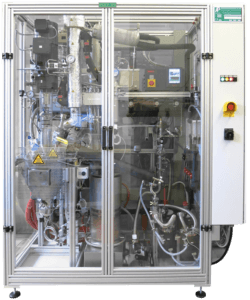

This system includes a 4-litre polycondensation reactor as the main reactor. The optimum amount of melt is approx. 2 kg. It has 2 steam lines. Firstly, there is a column as a dephlegmator followed by a condenser. This allows a highly volatile component to be separated and a component with a higher boiling point to be condensed and recovered at the same time. Additionally, there is a straight tubular condenser in which a component can be separated under high vacuum. The tubular condenser with double jacket allows easy cleaning of this part if it should become clogged with oligomers.

The high-temperature thermostat enables flow temperatures of up to 330 °C and is superimposed with nitrogen to protect the oil. The bottom valve with outlet nozzle is heated. The system is fully automated and equipped with an industrial process control system. A customizable recipe system for setting different process controls ensures flexible definition of the process steps and enables reliable operation.

Description:

- 4 L polycondensation reactor made of stainless steel 1.4404/1.4571.

- Mainly used for polyesters and polyamide.

- Allows esterification and polycondensation in the same vessel.

- Vacuum down to 0.1 mbar with integrated liquidified nitrogen trap..

- Max. allowable pressure 16 bar at 350 °C, operating pressure up to 12.8 bar @ 330 °C.

- 2 separate thermostats, one high temperature thermostat with a range of 40 to 330 °C for the reactor, the other for the partial condenser-column.

- Lifting system to allow handling by a single person.

Technical Specification

| Description | Unit | Value |

|---|---|---|

| Dimensions L x D x H | mm | 1750 x 800 x 2150 |

| Weight | kg | 688 |

| Electrical supply | 3P ~ 400 V / 50 Hz / 32 A | |

| Ambient conditions | °C | 0 to 35 |

| Temperature specifications | °C | -1 to 350 |

| Pressure data | barg | -1 to 16, recommended max. operating pressure 12.8 bar Vacuum 0.1-0.5 mbar abs. |

| Reactor total/heated volume | l | 5/4, min. Volume 1 l |

| Container | 2x stainless steel tanks (1 l) with glass cold trap (250 ml) and Dewar vessel | |

| Thermostats | kW | 9 / 50-330 °C and 2 / 60-140 °C |

| Other | Column with condenser, EC condenser, vacuum pump |