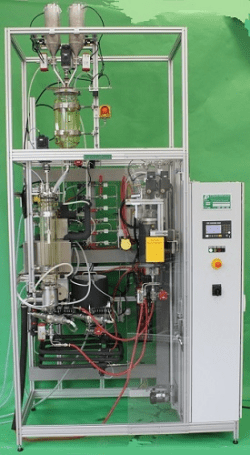

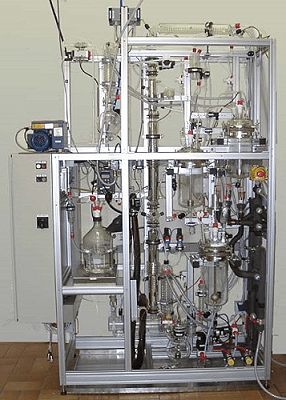

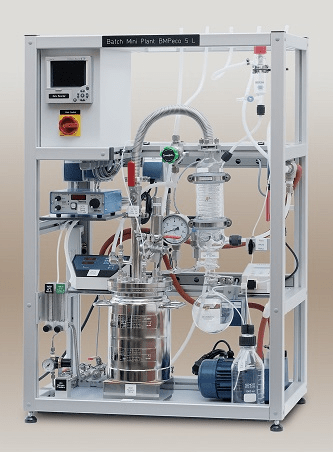

This emulsion polymerization plant consists of two stirred stainless steel reactors with capacities of 20 and 50 liters, each equipped with a lifting system for added convenience. These reactors are driven by variable speed, high power, explosion proof motors to ensure safe and efficient operation. The system also includes a dosing system for all components, thermostats for precise heating control and a recooler for optimal temperature management.

The reactors can be heated up to 180 °C by the thermostats and are designed for reaction conditions up to 200 °C and 14.4 bar.

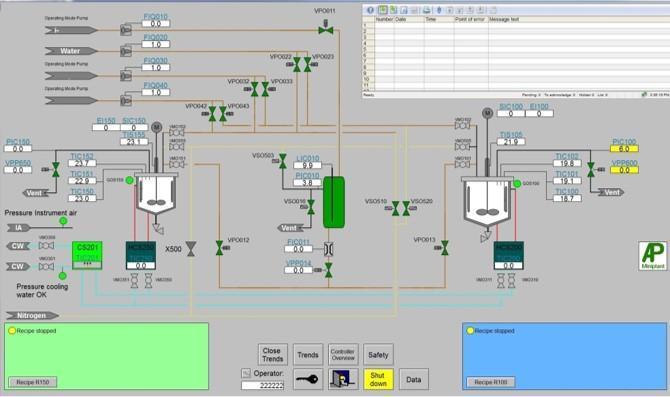

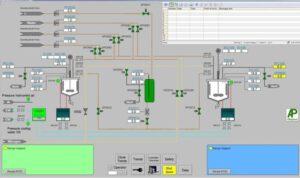

For maximum efficiency and ease of operation, the emulsion polymerization plant is fully automated with an industrial control system.

Features:

- 2 stirred stainless steel reactors (20 + 50 l) with lifting system.

- Speed controlled explosion proof motors.

- Dosing system, thermostats for heating, recooler.

- Fully automated with industrial control system.

Technical Specifications

| Description | Unit | Value |

|---|---|---|

| Dimensions L x D x H | mm | 1900 x 800 x 2200 |

| Weight | kg | 1400 |

| Electrical supply | 400 V / 50 Hz / 63 A | |

| Ambient conditions | 10 to 35 °C | |

| Temperature specifications | °C | -40 to 200 °C |

| Pressure data | bar | -1 to 18, recommended max. operating pressure 14.4 bar |

| Reactor type | Stainless steel stirred reactor (20 l + 50 l) with hydraulic lift systems | |

| Receiver tank | Feed vessel 10 l | |

| Thermostat | 10/20 kW heating/cooling -1 – 40 kW, 180 °C, water cooled |