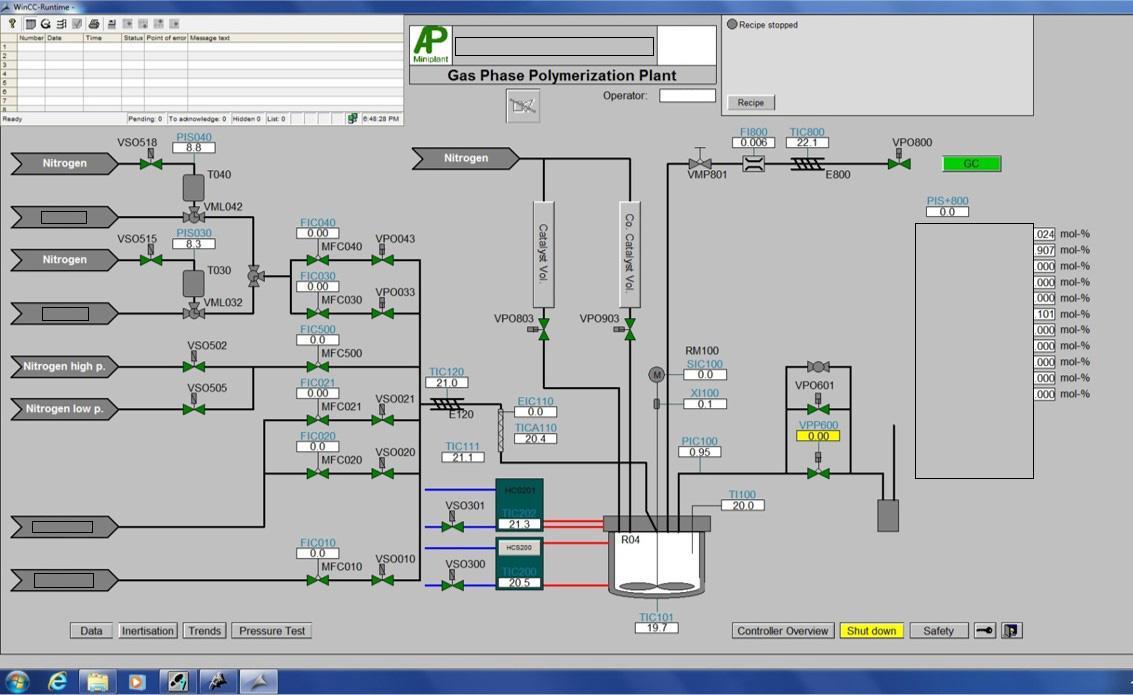

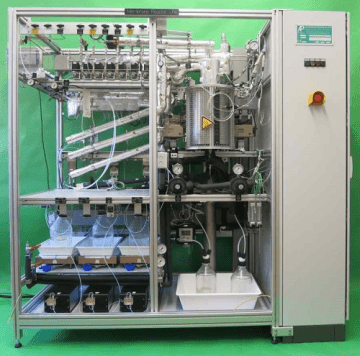

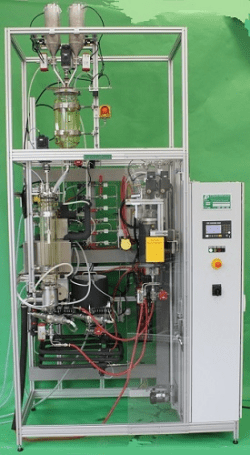

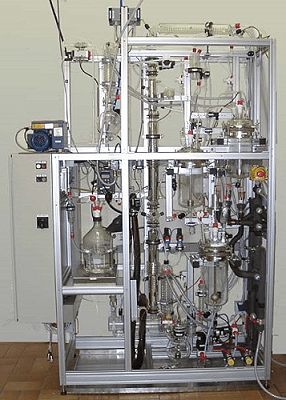

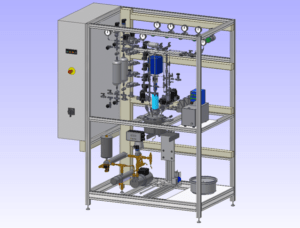

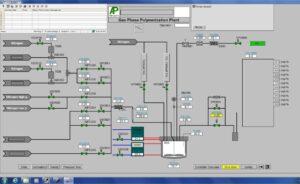

This gas phase polymerization plant uses a 1.8 liter reactor designed to operate at 175 °C and up to 40 bar operating pressure. This makes the system ideal for polymerization directly from the gas phase. An efficient stirring system ensures that the reaction phase is always optimally mixed. This system is equipped with a dynamic heating and cooling system that enables precise temperature control. The gas phase polymerization plant also has an integrated gas chromatograph for real-time analysis. The operation is fully automated and follows recipe-based protocols to ensure efficiency and consistency.

Features:

- 1.8 l reactor for up to 175 °C and 50 bar.

- Dynamic heating & cooling system.

- Integrated gas chromatograph.

- Fully automated recipe based operation.

Technical specifications

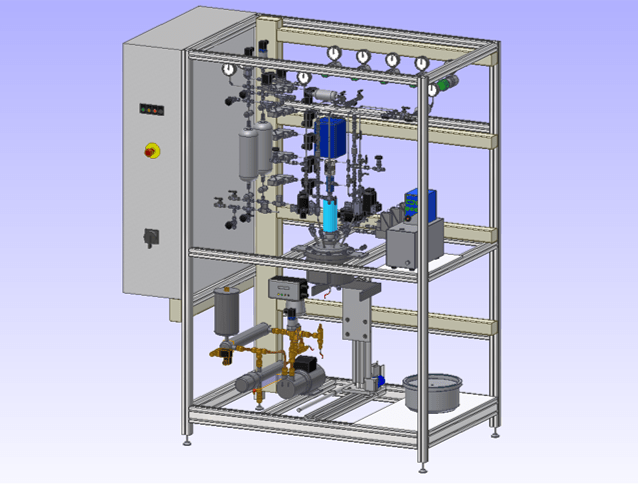

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 1550 x 900 x 1900 |

| Weight | kg | 360 |

| Electrical supply | 3 x 380 V AC, 60 Hz, 20 A, 3,5 kW | |

| Ambient conditions | °C | 10 to 35 °C, Max. humidity < 85 % |

| Pressure conditions | bar | PS -1 to 50, operation 0 to 40 bar |

| Temperature conditions | °C | -10 to 175 |

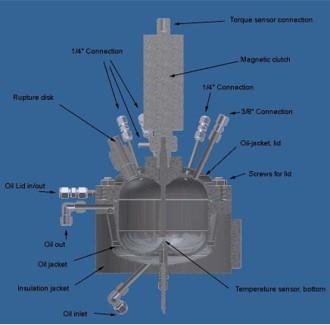

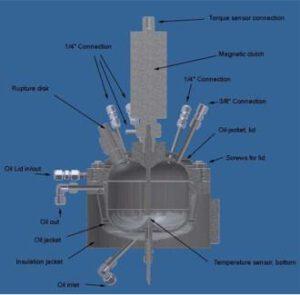

| Reactor type | Reactor with temperature measurement in the bottom and lid with heating/cooling jacket, material of construction is stainless steel 1.4404 (SS316L), agitator for swirling the gas phase in the reactor | |

| Reactor volume | l | 1.6 |

| Gas Supplies | Thermal mass flow controllers (examples) Nitrogen 10 – 500 g/h Ethylene 5 – 250 g/h Hydrogen 0.001 – 0.1 g/h | |

| Liquid or liquidified gas supplies | 2 Lines with 1 l pressure tanks, design pressure 50 bar | |

| Heating cooling system | AP-Miniplant highly dynamic heating and cooling system with circulation pump, pneumatically controlled mixing valve, electrical heater with 1.5 kW power, water cooled cooler. Total oil volume 2.5 l. | |

| Catalyst supply | Dosing units with 1, 2 and 10 ml, pneumatic syringe pump 10 ml adjustable |