In chemical and pharmaceutical development, unit operations form the foundation of process development.

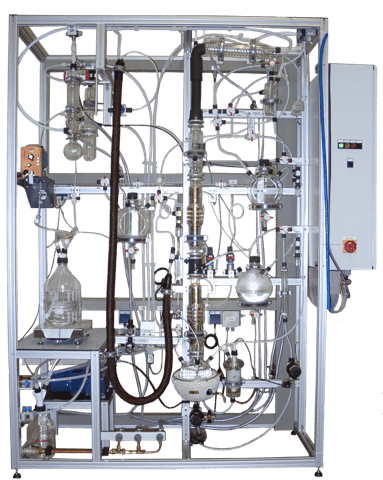

AP-Miniplant designs and builds tailor-made laboratory plants, miniplants and pilot plants in which key unit operations such as distillation, extraction, filtration or crystallization are implemented in a reproducible manner – including appropriate measurement, control and automation technology. This results in practical experimental plants for process development, scale-up and technical feasibility studies.

Gain an overview of our expertise and feel free to contact us if you have any questions about the plants shown or would like to request a quotation.

Whether batch or continuous: unit operations are the building blocks from which complete processes are formed. In an integrated laboratory or pilot plant, parameter windows, material properties, separation performance and energy input can be determined under realistic conditions, which is key for scale-up, safety and product quality in the chemical and pharmaceutical industries.

AP-Miniplant has many years of experience in implementing both batch processes and continuous processes, consisting of one or multiple unit operations, within fully automated laboratory plants. A selection of different unit operations that we have implemented can be found here.

Absorption

Absorption is used in pilot and research plants to selectively transfer components from gas or liquid phases into an absorption medium. Each system is engineered according to the specific material system, operating conditions and separation requirements. Automated control ensures stable operation and reproducible results.

No post found!

Adsorption

Adsorption processes are applied when components are selectively bound to solid materials, often under demanding temperature or process conditions. In addition, fixed-bed reactors filled with catalyst can also be used as test plants for catalysts or catalyzed reactions. Pilot plants are designed based on the chosen adsorbent, regeneration concept and operating parameters. This enables realistic process evaluation at pilot scale.

No post found!

Humidification & Evaporation

Humidification and evaporation processes are essential for controlling phase transitions and material conditions. Our systems enable controlled adjustment of moisture content and evaporation rate under defined operating conditions, whereby steam flows can be precisely regulated down to very low flow rates using our proprietary evaporation technology.

No post found!

Distillation & Rectification

Distillation is a key separation unit operation for complex mixtures. Our pilot plants are tailored to your material system, required separation efficiency and target throughput. Different column designs and operating modes can be implemented and automated as needed.

Distillation Plant made of Glass

This glass distillation plant can be used for research and educational purposes. It consists of…

Extraction

Extraction pilot plants are used to selectively separate target components from liquid or solid phases. Different solvents, contacting principles and operating parameters can be evaluated at pilot scale. Modular system designs enable flexible adaptation to various process concepts.

No post found!

Crystallisation & Precipitation

Crystallisation is one of the one of the most unpredictable unit operations. It requires precise control of temperature, concentration and mixing. Our pilot plants support the investigation of crystal formation, growth behaviour and product quality. Both batch and continuous crystallisation processes can be realised.

No post found!

Filtration

Filtration is widely used for solid–liquid separation in chemical and pharmaceutical processes. Pilot plants are individually designed according to particle properties, product requirements and separation behaviour. Automated operation supports reproducibility and reliable scale-up.

No post found!

Mixing

Mixing processes are crucial for material homogeneity and reaction control. Our systems take rheological properties, mixing intensity, and residence times into account. Thanks to our extensive experience in the field of polymerization plants, we can also offer solutions for highly viscous material systems. Different agitator and mixing concepts can be investigated and optimized on a pilot scale.

No post found!

Reactive rectification

Reactive rectification integrates chemical reaction and separation in a single process step. Pilot plants enable the evaluation of reaction kinetics and separation efficiency under realistic conditions. Each system is tailored to the specific reaction system and operating strategy.

No post found!

Drying

Drying processes are used to remove solvents or moisture from solid materials. Pilot plants are designed according to thermal properties and product sensitivity. Controlled operation provides reliable data for scale-up decisions.

No post found!

Evaporation

No post found!

Are you planning a pilot plant for chemicals or pharmaceuticals?

Briefly describe your process (material system, pressure/temperature, desired basic operations, analytics/PAT, scope of automation). We provide support from design to commissioning – as a miniplant or pilot plant.