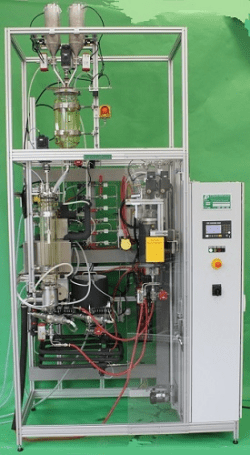

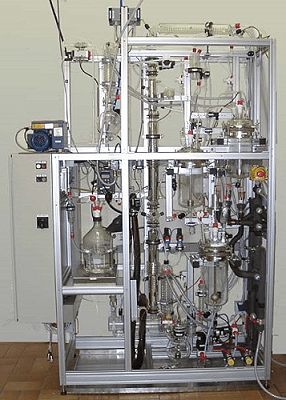

This 10-liter polycondensation plant includes a compact 10-liter stainless steel reactor. The entire system is designed to fit easily into a fume cupboard so that volatile hazardous substances can be continuously extracted. By combining the main reactor with an integrated rectification column and a subsequent phase separator, the system can be used for reactive rectification. This makes the plant suitable for a wide range of processes and allows the optimization of complex reactions. Thanks to the robust design, the reaction can be carried out under operating conditions of up to 16 bar and 350°C.

The polycondensation plant is controlled intuitively via individual controllers and easily accessible valves, which ensures high data quality and safe operation.

Further information on polymerization reactors as a functional unit can be found here.

Features:

- Polycondensation plant for polymerization in melts and suspensions.

- Compact design fits into a fume hood.

- 10 l stainless steel reactor.

- Including distillation and phase separator.

- Design properties: 16 bar, 350 °C.

Technical Specifications

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 1300 x 600 x 1960 |

| Weight | kg | 320 |

| Electrical supply | 3 x N/PE 230V AC, 50Hz / 16 A, 10kW | |

| Ambient conditions | 10 to 40 °C, max. humidity < 80% | |

| Pressure conditions | bar | -1 to 16 reactor -1 to 6 condenser and tank |

| Temperature conditions | °C | -40 to 350 |

| Distillation column | DN25 x 700 mm | |

| Vacuum | mbar | 9 |

| Reactor volume total / nominal | l | 11 / 10 |

| Material reactor/condenser/tubing | Stainless steel 1.4404/Stainless steel 1.4404/Stainless steel 1.4404, PTFE | |

| Data recorder | 6 channel Display + USB |