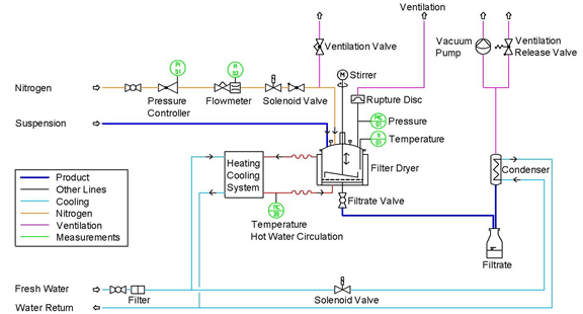

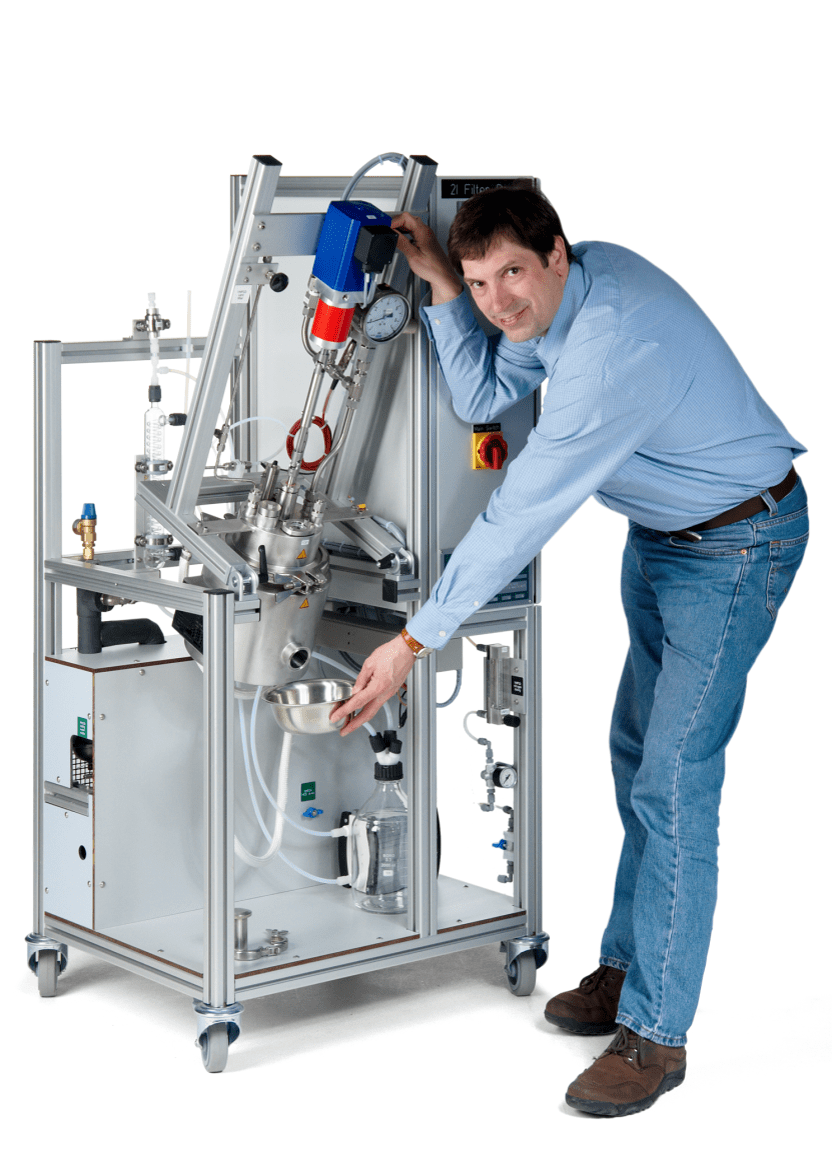

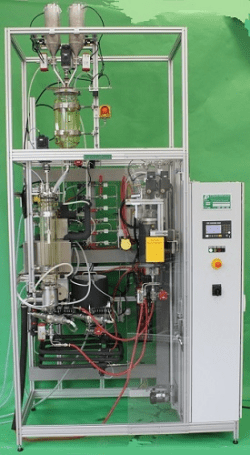

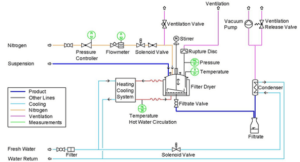

This combined filter and dryer consists of a heated jacket with a removable filter plate. The stirrer is adjustable in height and can be used to support the product removal. Minimum manual control is needed as the system allows the automated control of pressure, vacuum and temperature. The product can easily be removed by tilting the unit and then can be packed in individual bags in an airtight manner.

The apparatus can process suspensions up to 3 l with a maximum filter volume of 0.5 l.

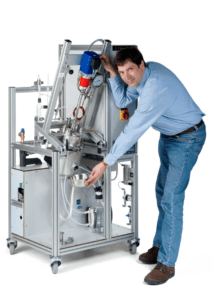

Compact Design

This combined filter dryer measures 730-1000mm x 600 x 1600 mm (W x D x H). This compact design enables a space-saving installation with excellent performance.

The entire unit is fitted with robust castors, giving you the flexibility you need to move and adapt your unit to different locations with ease.

Despite its compactness, the system has a range of integrated additional components to ensure you have everything you need:

- Heating-cooling system: Enables precise temperature control to optimize your processes.

- Filtrate collector: Ensures simple and efficient filtration and product collection.

- Vacuum pump: Providesreliable vacuum operation for your applications.

- Cooler: Regulates the temperature in your system and prevents overheating.

- Nitrogen purge: Provides protection against unwanted oxidation and creates a protective atmosphere.

- Automatic control: Enables easy control and monitoring of all processes.

- Sight glass and light glass: Enables visual monitoring and control of your processes.

Optimum Drying Process with our Combined Filter Dryer

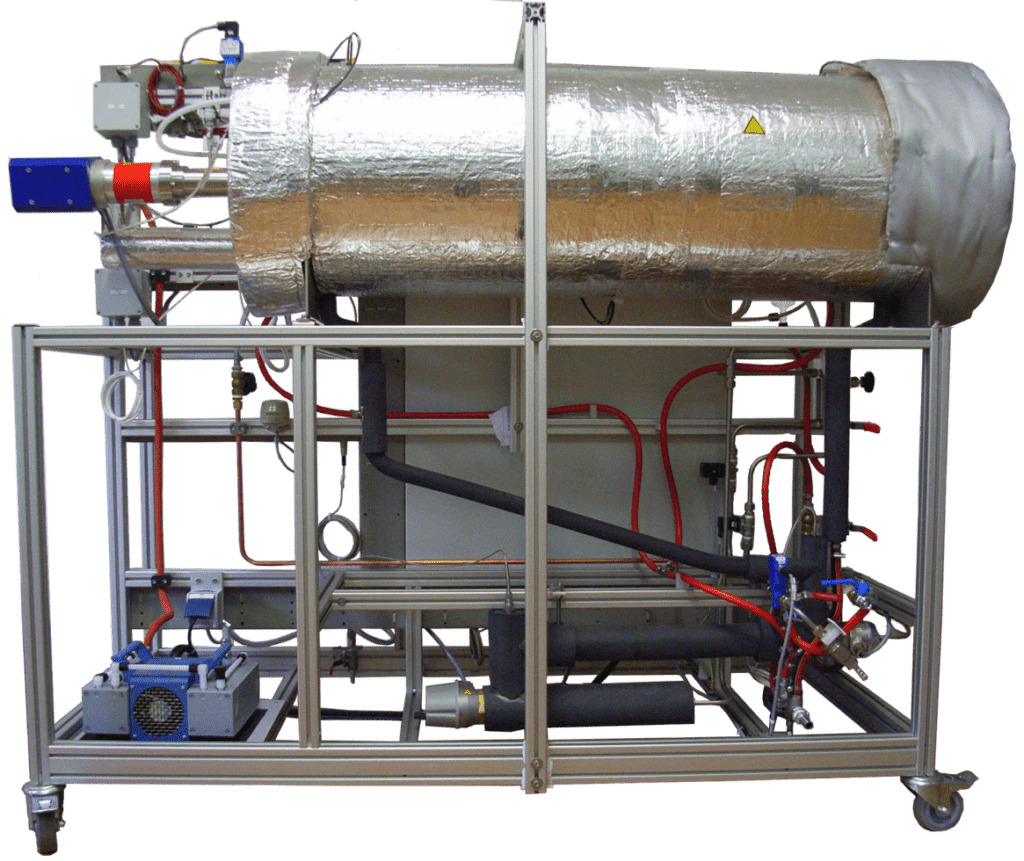

Pressurized water circulation system for filter jacket and plate: Our filter dryer has a pressurized water circulation system with a heating capacity of 1.5 kW, which enables temperatures of up to 140°C. It also includes water cooling with a heat exchanger for efficient temperature control.

Direct heating of the sandwich metal filter plate: This direct heating method ensures optimum heat transfer to the filter plate.

Jacket extension under the filter plate and additional insulation at the bottom: By extending the jacket under the filter plate and providing additional insulation at the bottom, we minimize heat loss and thus ensure an energy-efficient and homogeneous drying process.

Mixing of the filter cake with a height-adjustable agitator: The filter dryer is equipped with a height-adjustable agitator that enables the filter cake to be mixed evenly. This promotes an even and efficient drying process.

Efficient Filtration and Easy Maintenance

Replaceable sintered mesh filter plate with different mesh sizes (available from 1 to 200 µm): Our system is equipped with a replaceable sintered mesh filter plate. This supports mesh sizes from 1 to 200 µm.

No paper filter required but possible: By eliminating paper filters, we not only reduce consumables, but also improve heat transfer and mechanical stability during the stirring process. A device to use paper filters or cloth filters in available as an option.

Easy opening with clamp flange: The entire filter dryer is designed for easy access and maintenance. It has a simple opening mechanism with a clamping flange for quick and convenient filter plate replacement.

Easy-to-clean connections: Our system is equipped with easy-to-clean connections for hassle-free and efficient maintenance. The system also has an integrated cleaning-in-place cleaning system.

Maximum Flexibility

- Vacuum and pressure filtration options: Our system offers both vacuum and pressure filtration options. Choose the method that best suits your specific application.

- Controllable vacuum pump for gentle drying: The combined filter dryer has a controllable vacuum pump that enables a gradual pressure reduction. This controlled process ensures gentle drying, which guarantees the quality of your products.

- Controllable nitrogen purging and intertization: For applications that require a controlled atmosphere. Our system allows the use of nitrogen purging and inerting to maintain the desired conditions.

- Large opening with adaptable conical ground joint (size 29/32): The system allows for flexible adaptation to size 29/32 conical ground joints or direct product removal. This ensures compatibility with a wide range of laboratory glassware.

Fast Product Removal

Tiltable construction for solid removal without opening the lid: The tiltable design allows solids to be removed without having to open the lid. This design simplifies the maintenance process and minimizes downtime.

Side discharge opening (size 40 mm) with clamping flange and plug: The system has a side discharge opening with a size of 40 mm. Complete with clamping flange and plug for safe and easy access.

Option to connect a plunger valve for product removal without air contact: For added convenience and product purity, our system can be fitted with a plunger valve. This ensures product removal without contact with the atmosphere.

Easy replacement of standard laboratory bottles as filtrate vessels: Use standard laboratory bottles as filtrate vessels. This allows quick and easy replacement, simplifies the process and reduces downtime during operation.

Reliable Automation

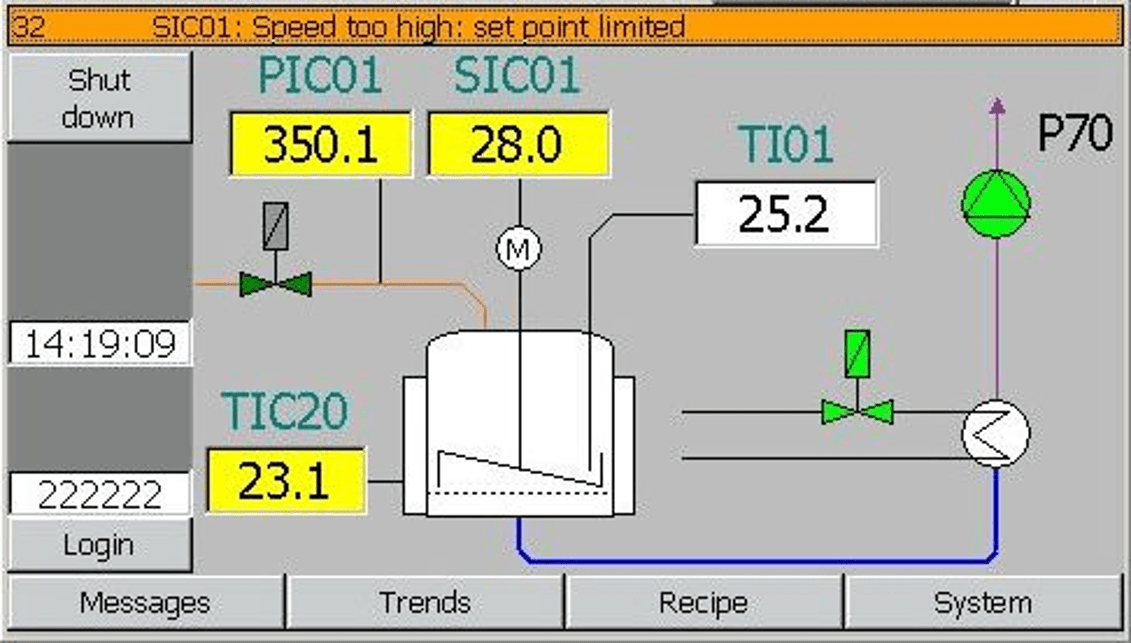

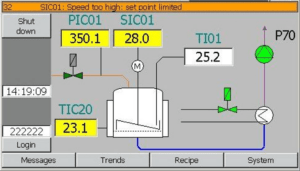

- Industrial-grade touch panel control system: Our system is equipped with an industrial touch panel control system, ensuring robust and reliable operation.

- User-friendly touch panel user interface: The touch panel user interface provides an intuitive and user-friendly platform for controlling and monitoring the system.

- Configurable recipe steps: You have the flexibility to configure recipe steps, allowing individual and precise control of your processes.

- Safety measures for temperature and pressure: Safety is a top priority and the system includes functions for monitoring and controlling temperature and pressure. This ensures safe and reliable operation.

- Text-based status and alarm messages: The system provides detailed text-based status and alarm messages that provide real-time information about the system’s performance and any problems that may occur.

- Audible alarm: For added safety and awareness, an audible alarm is integrated into the system to alert operators to critical situations or alarms.

| Description | unit | Value |

|---|---|---|

| Dimensions L x D x H | mm | 1000 x 600 x 1600 |

| Weight | kg | 182 |

| Pressure in circuit | bar | 0.06 to 4.5 |

| Temperature | °C | -15 to 140 °C |

| Filter volume and material | L | 3 l, stainless steel 1.4404/316L |

| Receiver tank | 2 (made of glass) | |

| Filter area | cm² | 105 |