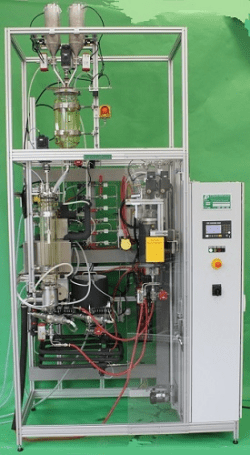

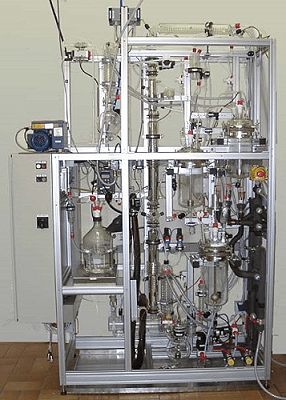

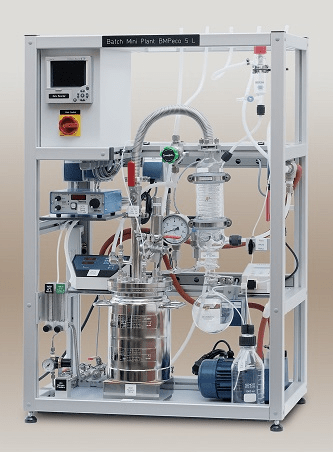

We have developed this polymerization reactor system with a compact design so that it is suitable for installation in a standard laboratory fume cupboard. At its heart is a replaceable stainless steel pressure reactor for polymerization, which ensures pressure and temperature resistance and is extremely durable.

Our plant can be operated with both liquid and gaseous reactants and has an additional 1-liter solids feed. The pressure reactor can therefore be used flexibly at up to 175 °C and 32 bar. Additionally, the plant is fully automated and has an industrial control system. This increases reliability and overall efficiency, making it a great choice for various polymerization applications.

Features:

- Compact design that fits into a lab fume cupboard.

- Stainless steel pressure reactor for polymerization, exchangeable.

- Max. allowable pressure 40 bar at 175 °C, recommended max. operating pressure 32 bar.

- Liquid and gas feed, 1 L solid feeder.

- Fully automated with industrial control system.

Technical Specifications

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 1400 x 1150 x 2000 |

| Weight | kg | 400 |

| Electrical supply | 380 V, 60 Hz, 16 A | |

| Ambient conditions | 5 to 40 °C, max. humidity: 90% @ 20 °C | |

| Pressure conditions | bar | PS = -1 to 40, opreation max. 32 bar |

| Temperature conditions | °C | Operating temperature 175 °C Design temperature reactor: 200 °C |

| Stirrer torque | Nm | 5 Nm |

| Other | 2x sight glass, air heater, tanks | |

| Solid and slurry supply | 1 l solid feeder |