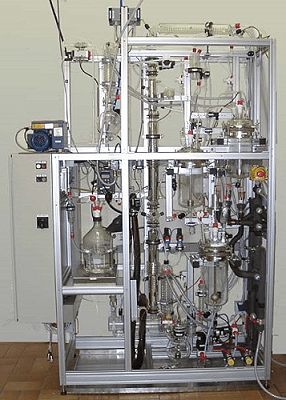

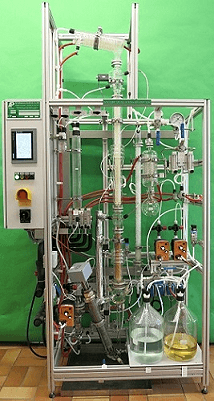

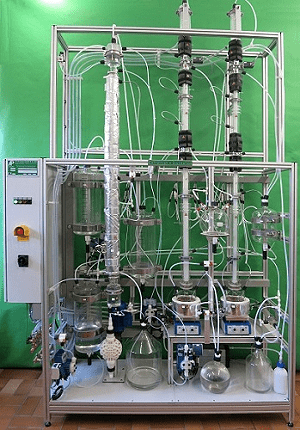

Our extraction column with 2-stage distillation offers comprehensive functions and precise control options for your industrial process requirements. This unit has been carefully designed and engineered to enable the efficient separation and processing of mixtures in multiple stages.

Extraction can be carried out in pulses, with phase separation possible at both the lower and upper ends. The PTFE sieve trays enable effective mixing. The downstream rectification columns made of laboratory glass can be used to further purify the extraction products. Magnetic heating stirrers, heating sleeves and an automated return flow divider enable precise control of the rectification process. 4 dosing pumps, 8 storage and product vessels as well as a controllable vacuum pump up to 20 mbar allow flexible adaptation of operation management. Thanks to the high degree of automation and extensive sensor integration (temperature, flow rate and pressure), the system can be used for various processes in research and development.

Features:

- Pulsating extraction column with top and bottom phase separation.

- PTFE sieve trays allow efficient mixing of substances.

- Glass distillation columns: With magnetic heating stirrers and heating jackets for evaporation.

- Operating range: 20 mbar to 1.5 bar abs. Up to 150 °C.

- Upright condenser with an automated shaking funnel for precise recirculation.

- Automation and monitoring: With automation system and SCADA software for precise control and monitoring.