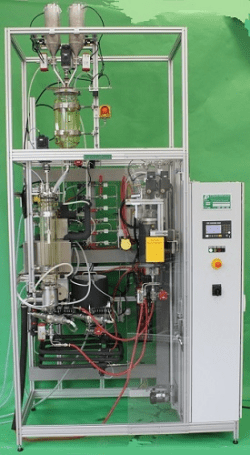

This glass reactor plant is characterized by the exchangeable reactor and a particularly high degree of flexibility. The interchangeable glass reactor is available in 5 l, 10 l or 15 l volumes. The process connection and instrumentation are made via connection points in the DN200 cover. The glass reactor system is equipped with a Profibus/Profinet plug-in connection, which ensures seamless integration into various systems. The slim and space-saving frame design optimizes the use in confined spaces.

With an integrated pump, feed vessels and measuring probes, you always have full control over your process. In addition, our glass reactor plant can be made GMP-compliant (Good Manufacturing Practice) on request and meets the high quality and hygiene standards of the pharmaceutical industry.

Features:

- Exchangeable glass reactor with one DN200 lid.

- Profibus/-net plug in connection.

- Slim and space-saving frame design.

- GMP prepared.

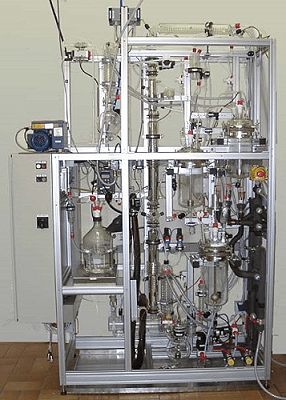

Technical Specifications

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 570 x 570 x 2383 |

| Weight | kg | 168 |

| Electrical supply | 230 V / 50 Hz / 13 A, 3 kW | |

| Ambient conditions | 10 to 40°C, max. humidity at 40°C: < 80% | |

| Pressure conditions | bar | vacuum up to 0.3 bar |

| Temperature conditions | °C | -20 – 100 °C – others on request |

| reactor type | stirred glass reactors (5 L, 10 L or 15 L) adapted off lid (DN200) | |

| Pump | ml/min | 0.001 to 2900 depending on the tube size |

| Stirrer speed | rpm | 400 |

| Temperature and level measurement | Nm | PT100 and photoelectric proximity switch |