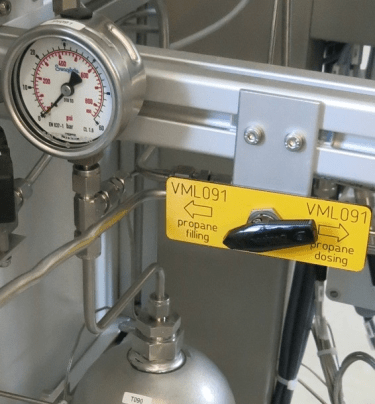

AP-Miniplant offers a system for dosing liquid gas or liquids under pressure, in which the liquid gas and the inert gas that builds up pressure are separated by a membrane. This avoids the saturation of the liquid by the inert gas. For this purpose, the membrane container is filled with the liquid gas on one side. On the other side, an inert gas is used to build up the pressure. The pressure built up in this way is used for the actual dosing by means of a Coriolis or other mass flow regulator. This prevents the formation of bubbles due to the gas being released.

The prerequisite for applicability is the chemical resistance of an elastomer diaphragm, e.g. made of FKM (e.g. Viton®), NBR or EPDM. The available size of the templates depends on the pressure.