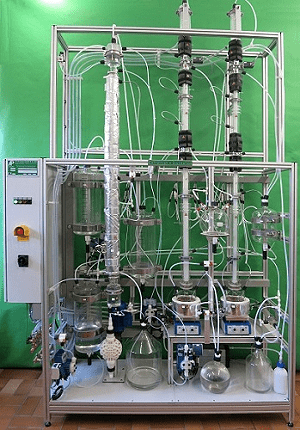

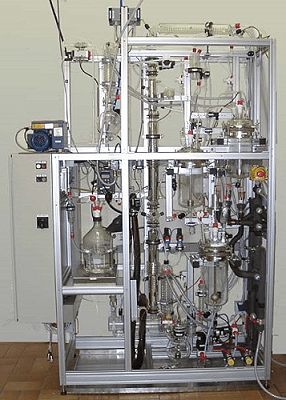

This multi-stage evaporation plant with a two-stage evaporation system and a capacity of 10 liters per evaporation stage has been designed as an education plant to demonstrate multiple effect stack evaporation. The first stage of this plant features an electric heating, which ensures precise and controlled heating of the substances to be vaporized. The second evaporation stage is carried out in a vacuum. The vapors produced in the first stage serve as a heat supply for the second stage. This results in an energy-efficient mode of operation, whereby the scalability of energy-efficient processes can be validated.

The precise control options of the multi-stage evaporation plant play a central role by enabling optimum adaptation to the specific operating parameters.

Features:

- Energy efficient evaporation in two stages.

- Electrical heating and precise control in the first evaporator stage.

- Heat integration and use of vapor from the first stage for evaporation in the second stage under vacuum.

- Glass evaporators and condensers to observe the process.

- Feedpump, condensate pump and plastic canister as product receiver for quick change of media