Our Fuel Gas Pressure Reduction Training Plant was specially developed for training and education purposes. It enables the simulation of the Joule-Thomson effect. This is achieved by utilizing humidified hot air.

One notable feature of this training plant is its ability to introduce disruptive factors. It accommodates three gas consumers of varying sizes, allowing for automatic switching between them.

Moreover, the training plant incorporates a sight glass, enhancing the educational value by enabling observation of the dew-point during pressure changes. This visual element helps students and trainees grasp the concept more effectively, connecting theory to practical observations.

Features:

- Simulation of the Joule-Thomson-Effect.

- Use of humidified hot air for the simulation.

- Three gas consumers of different sizes can be automatically switched as a disruptive factor.

- Sight glass for observation of dew-point during pressure changes.

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 2000 x 800 x 1800 |

| Weight | kg | 405 |

| Electrical supply | 3P ~ 380 V / 60 Hz / 20 A | |

| Ambient conditions | 10 to 35 °C | |

| Pressure conditions | bar | 0 to 6 |

| Temperature conditions | °C | -10 to 180 |

| Thermostat | 1.2 kW | |

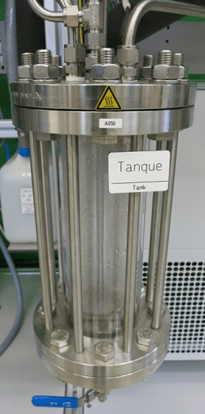

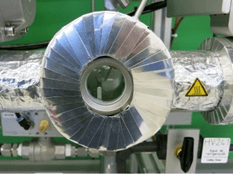

| Other | 2x sight glass, air heater, tanks | |

| Automation | Industrial control system with training programs |