Project Workflow – Customized Miniplant Projects

A clearly structured project process is crucial to the success of miniplant systems.

We support you from the initial inquiry to commissioning—transparently, cooperatively, and with clearly defined project phases.

Your Project with AP-Miniplant

When you order your customized miniplant from AP-Miniplant, you benefit from our extensive experience and efficient project execution. We typically deliver your tailored system within 6–12 months after the order is placed.

How We Work – Step by Step

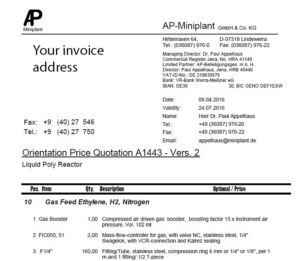

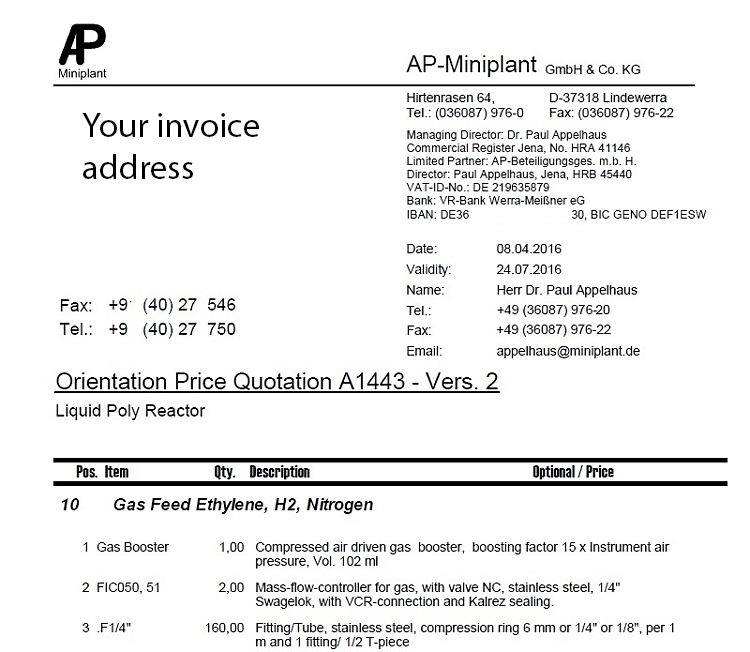

Inquiry & Quotation

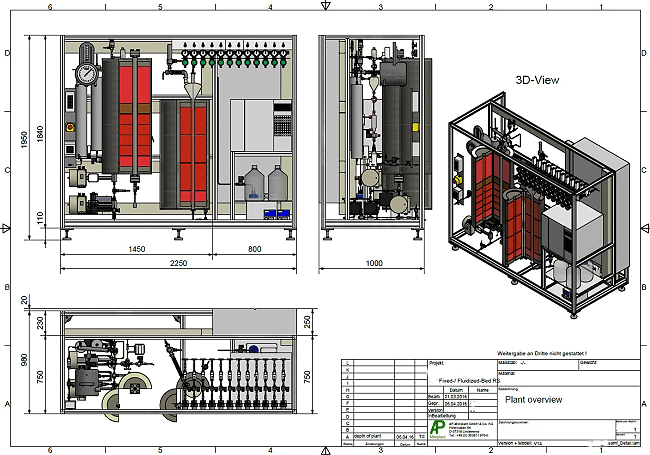

Concept Development

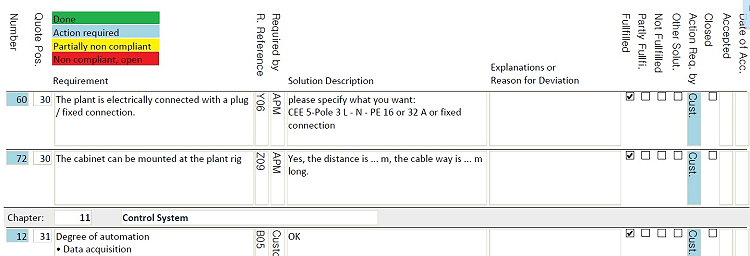

Detailed Planning & Customer Approval

Construction & Automation

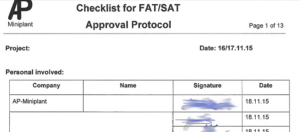

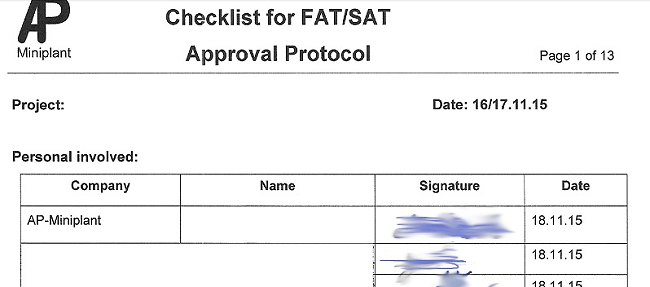

Testing & Final Approval (FAT)

Delivery & Commissioning

Inquiry & Quotation

Concept Development

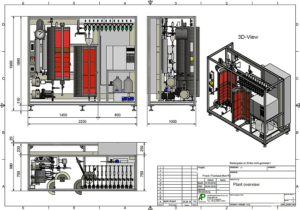

Detailed Planning & Customer Approval

Construction & Automation

Testing & Final Approval (FAT)

Delivery & Commissioning

*Approximate values, depending on project scope, specifications, and coordination processes

You Need a Quotation for a Laboratory or Pilot Plant?

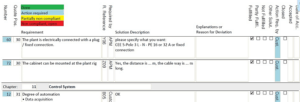

To prepare a customized quotation for your laboratory or pilot plant, we require specific technical and process-related information. This allows us to design a solution that is precisely tailored to your requirements and to calculate costs reliably.

The more detailed the information provided, the more accurately and efficiently we can prepare your offer.

Please provide the following details as far as possible:

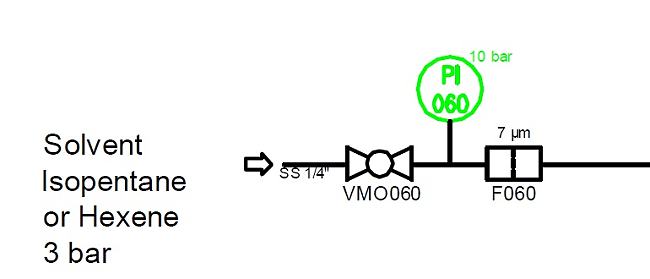

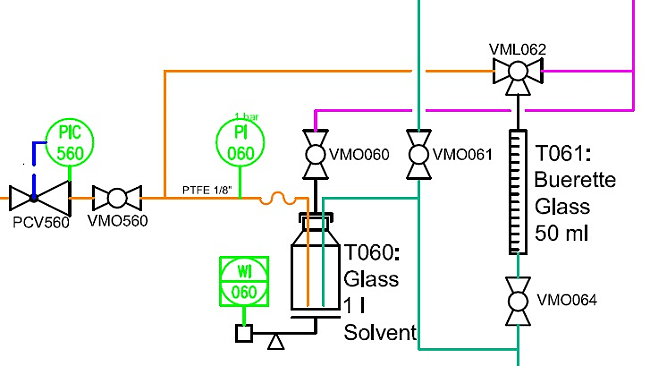

- General description of the process

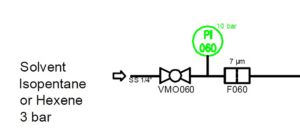

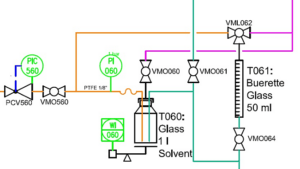

- Process flow diagram (PFD) including layout and interfaces

- Type, number and size of main equipment

- Operating conditions

- Minimum and maximum pressure

- Minimum and maximum temperature

- Materials of construction

- Flow rates of feed and product streams

- Physical state and phase of all process streams

- Installation site conditions, such as:

- Available space

- Ambient conditions

- Ventilation requirements

- Special requirements, for example:

- Explosion protection (ATEX)

- High corrosion resistance

- GMP compliance or cleanroom integration

We usually prepare quotations free of charge.

Detailed information on customer inputs, risks, and special cases can be found in the FAQ section below.

Frequently Asked Question

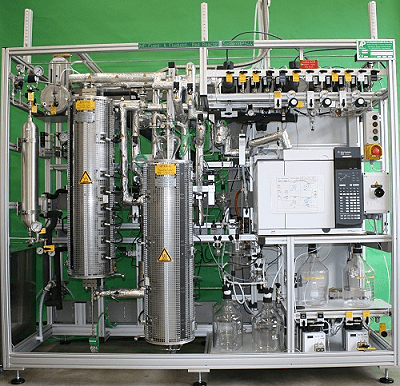

Project Planning in Pictures