Falling limits for NOx compounds in car exhaust gases are leading to the need to continuously improve existing automotive catalytic converters. Storage catalytic converters are not sufficient to meet the requirements of today’s emission standards, such as the Euro 6 standard, especially in high-consumption passenger cars. For this purpose, Selective Catalytic Reduction (SCR) catalytic converters are used, which are currently the most efficient catalytic converters for reducing NOx compounds and can reduce them by up to 90 %. An SCR test system can be used for the development of SCR catalytic converters.

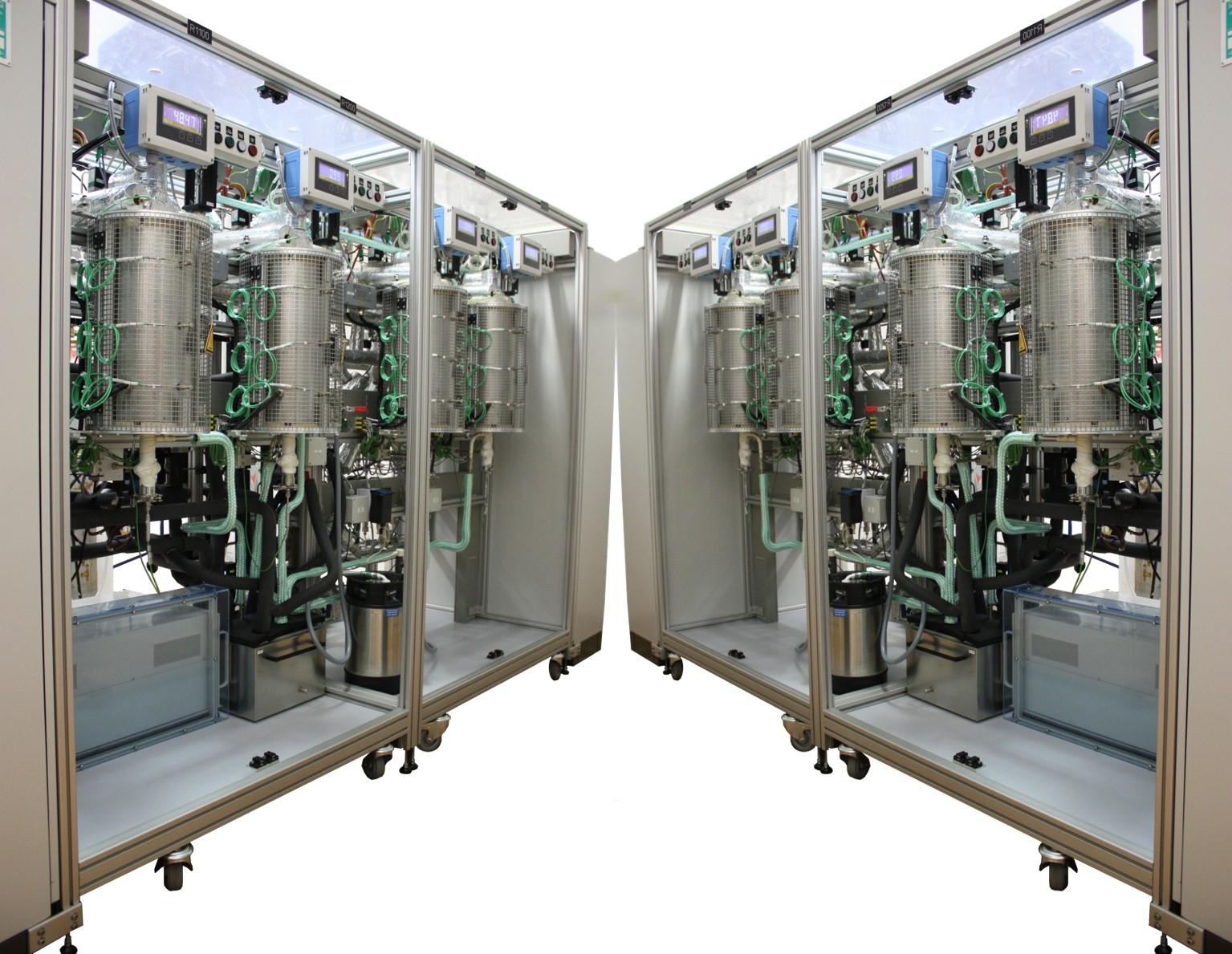

As part of our AP-SmartPlant product line, AP-Miniplant offers a fully automated and proven test system for the further development and optimization of SCR catalysts. Our flexible SCR test system provides a variety of different test options such as service life test, test of possible operating conditions or dynamic performance test.

Main Features SCR Test System:

- Designed for testing of catalyst core samples with 1″ bore and variable length, typically between 3″ and 10″.

- Modular design for adaptation to specific test requirements.

- Automatic control of gas flows by mass flow meter

- Steam generator for generating water or hydrocarbon steam with precise dosing – even for low steam quantities

- Optional monitoring of the input and output concentration with connection to an analyzer (e.g. gas chromatograph)

- SCR test system operating limits: up to 4 bar, up to 1000 °C

- Reactor diameter and length can be adapted to customer requirements.

Technical Data

| Unit Description | Unit | Value |

|---|---|---|

| Electrical supply | 400 V, 50 / 60 Hz, 50 A | |

| Ambient conditions | 10 to 35 °C, max. humidity < 80 % | |

| Pressure conditions | bar | 1 – 4 bar abs. |

| Temperature conditions | °C | Reactor: 10 – 850 °C, optionally – 1000 °C Max. Furnace temperature: 1200 °C |

| Reactor type | Quartz glass reactor embedded in a pressure-resistant stainless steel tube (1.4841) | |

| Analytical system | FTIR, oxygen sensor, others possible | |

| Gas supplies | On request. Up to 6000 L/h and 12 different supply lines | |

| Liquid supplies / evaporators | Dosing unit and evaporator for water and hydrocarbon. Optional: Ion exchanger cartridges for water treatment. | |

| Exhaust gas treatment | Condenser, gas cooling and dilution |

Additional Functions

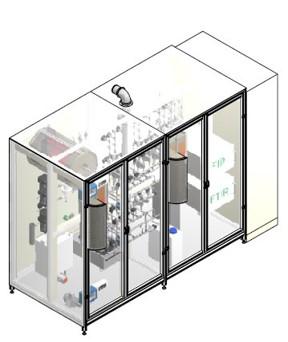

- Transparent closed frame with doors on both sides.

- SCR test system mainly made of standardized components for easy modification and availability of spare parts.

- Clamp closure for quick sample removal.

- Additional heating and temperature-controlled bath cooling to prevent condensation in supply and analysis lines.

- Industrial Siemens automation system.

- Simatic Batch recipe control system for easy creation of test sequences.

- Suitable for autonomous operation thanks to integrated safety technology.

- Maximum flexibility in recipe definition.

Do you need an extended SCR test system? As part of our AP-MyPlant product line, we offer you comprehensive customization options such as

- Multi-reactor systems.

- Additional inlets for gases, liquids and vapors.

- Furnaces with tubes for specific applications.

- and much more.