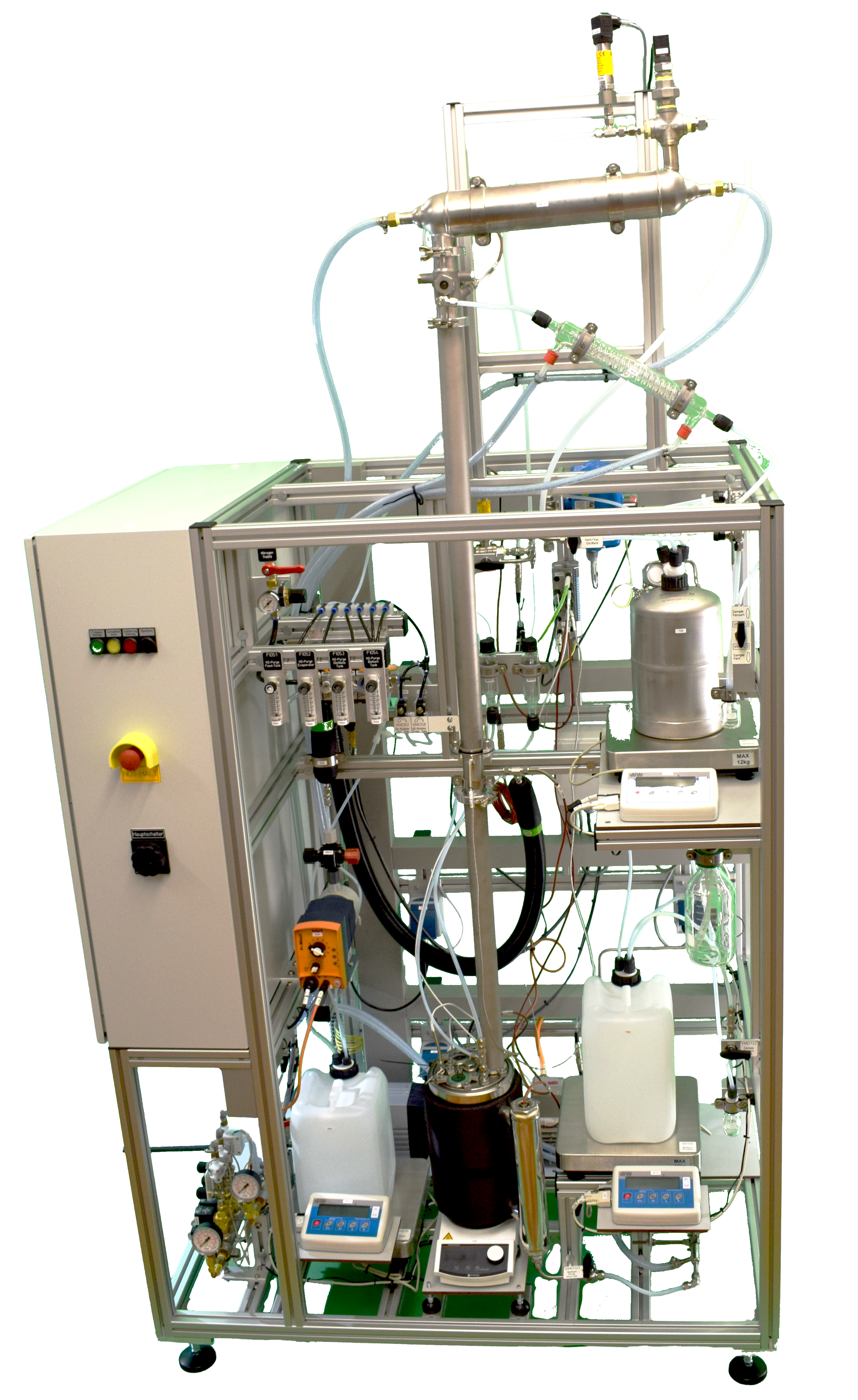

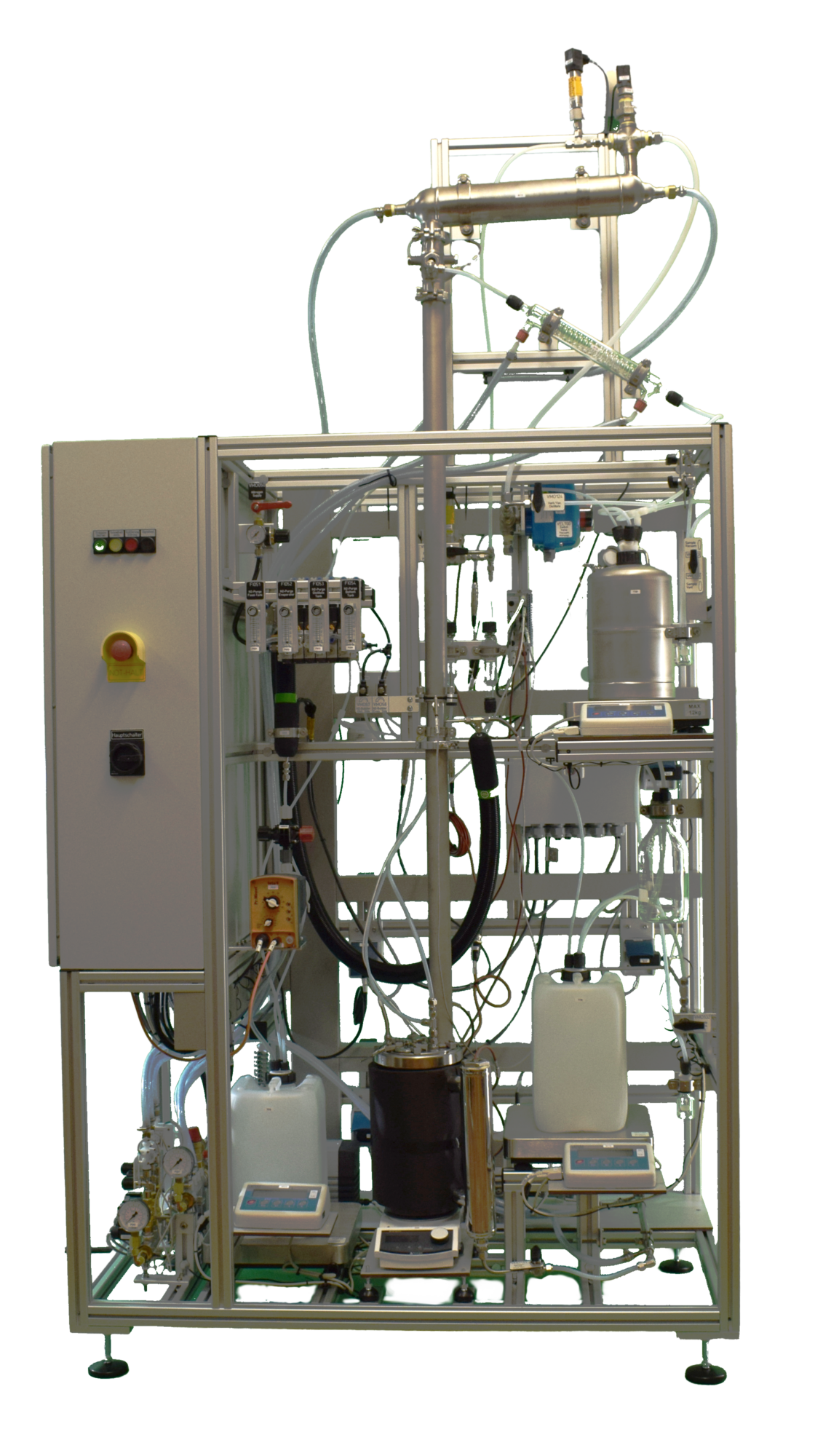

This system is a distillation plant that can be used in both continuous and batch operation. It is a reliable system with a distillation column made of borosilicate glass or stainless steel, robust automation and comprehensive sensor technology.

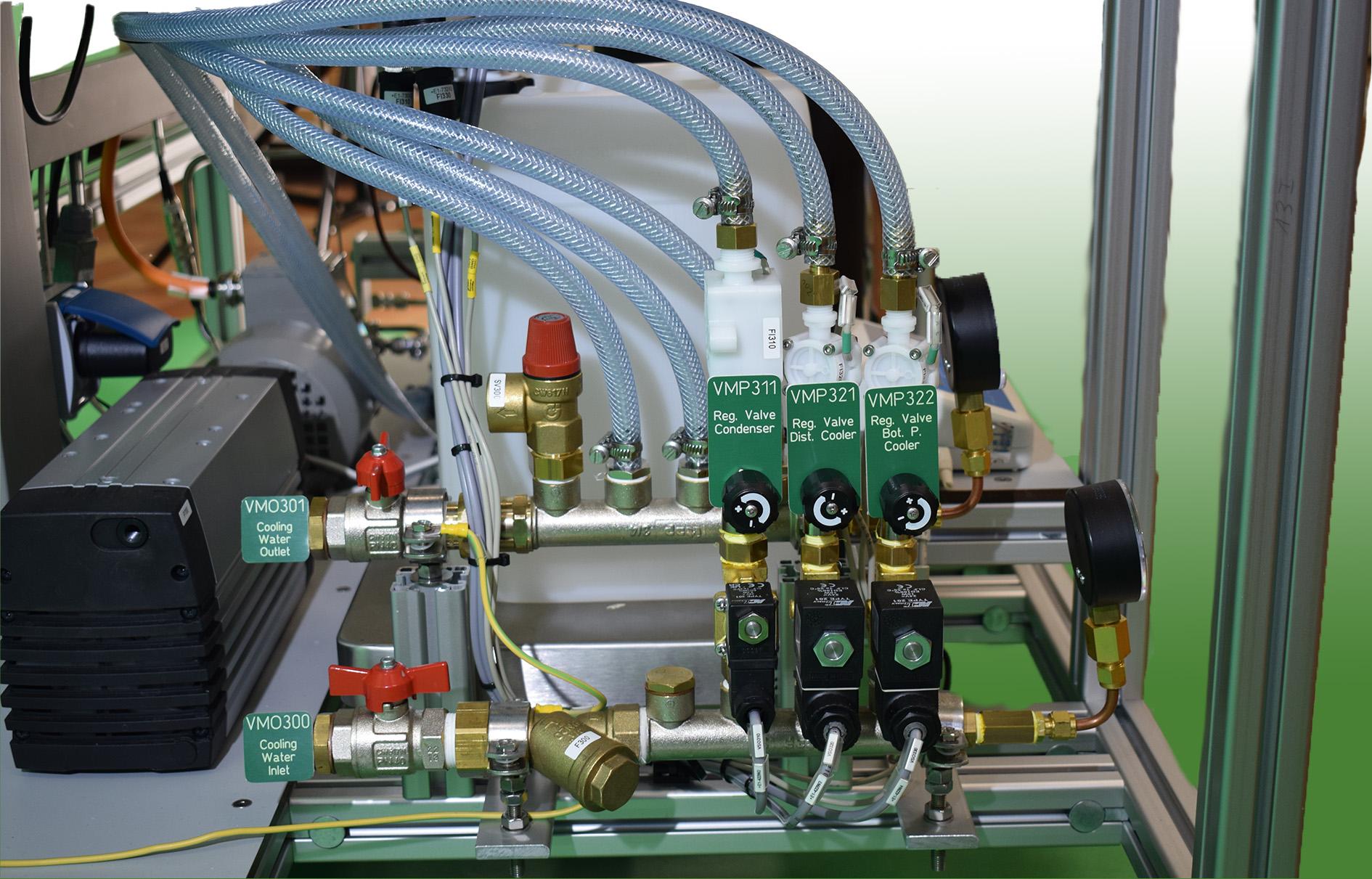

Random or structured packings can be freely selected as internals. The system is suitable for rectification in the vacuum to normal pressure range at temperatures between 45 and 150 °C. Thanks to various process control options, e.g. via temperature or differential pressure, as well as exchangeable containers for feed, distillate and sump, your product streams can be purified efficiently, safely and without contamination.

The column sections are interchangeable and can be manufactured as glass or stainless steel columns. Individual column sections are flexibly connected to each other using small vacuum flanges. The column can be equipped with either insulation or trace heating.

Our adjustable evaporator has a maximum output of 1.5 kW and an evaporator volume of 5 l, which ensures sufficient gas and liquid loads. The distillation capacity is between 1 and 4 L/h, depending on the medium and operating mode. Due to the position of the stirrer in the lower part of the evaporator, the sample can be almost completely evaporated during batch rectification. The level measurement on the side, which regulates the sump draw-off, ensures a constant fill level during continuous operation. Distillate is collected in a vacuum-proof stainless steel container or alternatively in a glass flask. Samples can be taken at any time via manual valves.

Flexibility in the control system

The system is fully automated and is controlled via an S7/1500. You can control the rectification process precisely via differential pressure or heat output, depending on your requirements. This flexibility enables optimum adaptation to different production processes. Customizable recipes allow you to define different process steps independently and generate reproducible results.

Innovative details

Our distillation column has been carefully planned and designed for optimum test results. By manufacturing the evaporator and condenser from durable stainless steel, we can guarantee four times better heat transfer compared to a borosilicate glass apparatus. The sophisticated stainless steel reflux divider ensures precise adjustment of the reflux ratio and even liquid distribution. Integrated sight glasses and numerous temperature, pressure, flow and level sensors allow you to keep an eye on your process at all times.

Versatile application options for our distillation column

Whether you want to recover solvents, carry out product purification or recycle electrolytes – our distillation column is versatile and ensures first-class results.

Technical data

| Description | Unit | Value |

|---|---|---|

| Dimensions L x D x H | mm | 1560 x 660 x 2360 |

| Unit weight | kg | 550 |

| Electrical connection | AC 230V / 60Hz – 10 %, 1-phase system without neutral conductor | |

| Evaporation capacity | kW | up to 1.5 (more on request) |

| Temperature specifications | °C | 45 to 150 |

| Pressure specifications | bar | -1 to 0 (higher pressure range possible on request) |

| Column | Stainless steel (1.4404) or borosilicate glass 3.3 | |

| Packing | Random or structured packing | |

| Materials with product contact | Stainless steel (1.4404), borosilicate glass 3.3, PTFE | |

| Liquid feed | Plastic or stainless steel canister | |

| Additional equipment | Return flow divider, vacuum pump, feed extraction points, differential pressure sensor |

Do you need even more customization options or would you like to combine several process steps? We will be happy to make you an individual offer.