We offer different automation systems depending on the complexity of the system. We will find the most economical and reliable solution for you. A reliable automation system is the key to a dependable production or research facility.

Our solutions offer comprehensive control over your systems and enable easy integration into existing infrastructures. Find out more about the benefits of our automation systems and how they can increase the efficiency of your process engineering applications.

Individual Controllers and Data Loggers

We offer a particularly cost-effective solution for systems consisting of just a few devices. Our combination of robust data recorders with reliable process controllers for selected process variables enables precise control without unnecessary effort.

You benefit from direct and intuitive setting of the necessary process parameters at low cost. The data loggers continuously record all measured values and transmit them via an Ethernet or USB interface, for example.

Our Standard Automation System

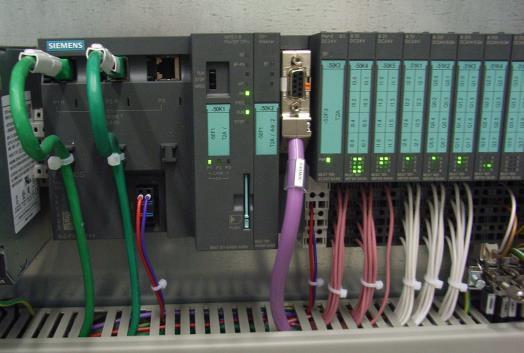

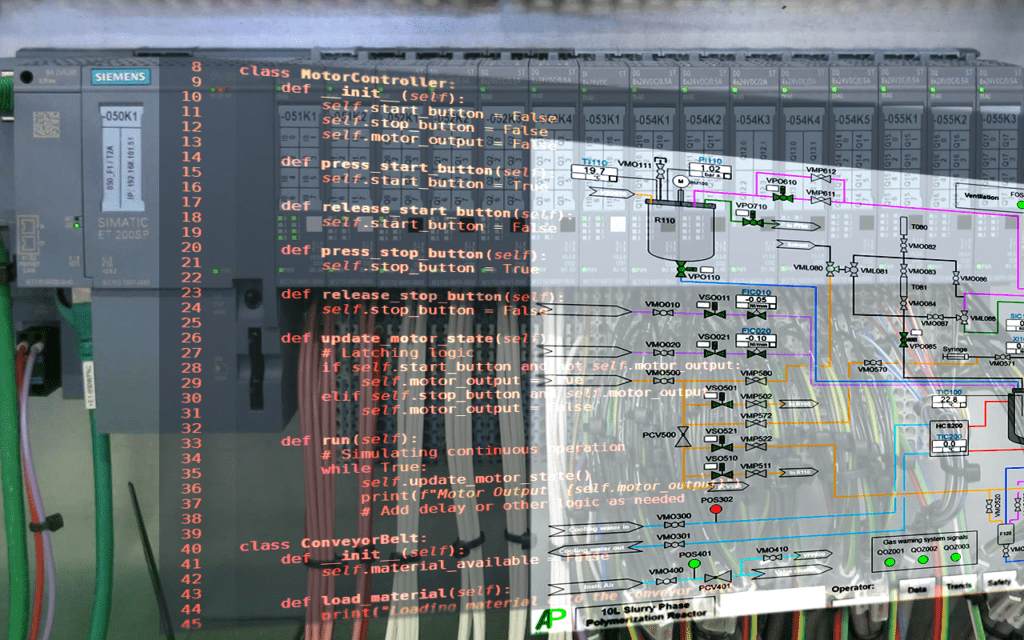

We use industrial control systems for most of our plants, which guarantees a high degree of flexibility and reliability. We use Siemens controllers from the S7/1500 series with Profinet connection for a default level of automation. The plant control system is operated via a Windows PC, which is equipped with the powerful Simatic WinCC SCADA system.

These components offer reliable control and monitoring of your processes over a long period of time. You also benefit from the long support guarantees for industrial control systems.

We create our control programs individually according to your specifications. You receive a preconfigured and tested program. Of course, you can set control parameters, warning limits and sequences individually at any time and further optimize your processes. Our reliable automation solution increases the efficiency of your systems and helps you to maintain control over your processes.

Industry 4.0-ready Automation

Discover our Industry 4.0-ready automation solutions. In addition to industrial controllers from the Siemens S7/1500 series, we rely on the advanced, web-based WinCC Unified operating and monitoring system. This extremely scalable system allows you to choose between PC and industrial panel platforms and even offers options for operation in hazardous areas using suitable panels. Our Industry 4.0-ready automation systems can help you take your process engineering applications to the next level of digitalization. Thanks to consistent data storage, globally valid standards and uniform interfaces, the system enables perfect interaction between all automation components and higher-level systems.

With our remote monitoring and control systems, you always have your systems under control, no matter where you are. Use state-of-the-art automation solutions to monitor and optimize processes in real time. Discover the possibilities of remote monitoring and control and stay optimally equipped for future challenges.

Highly Modular Automation for Modular Plants

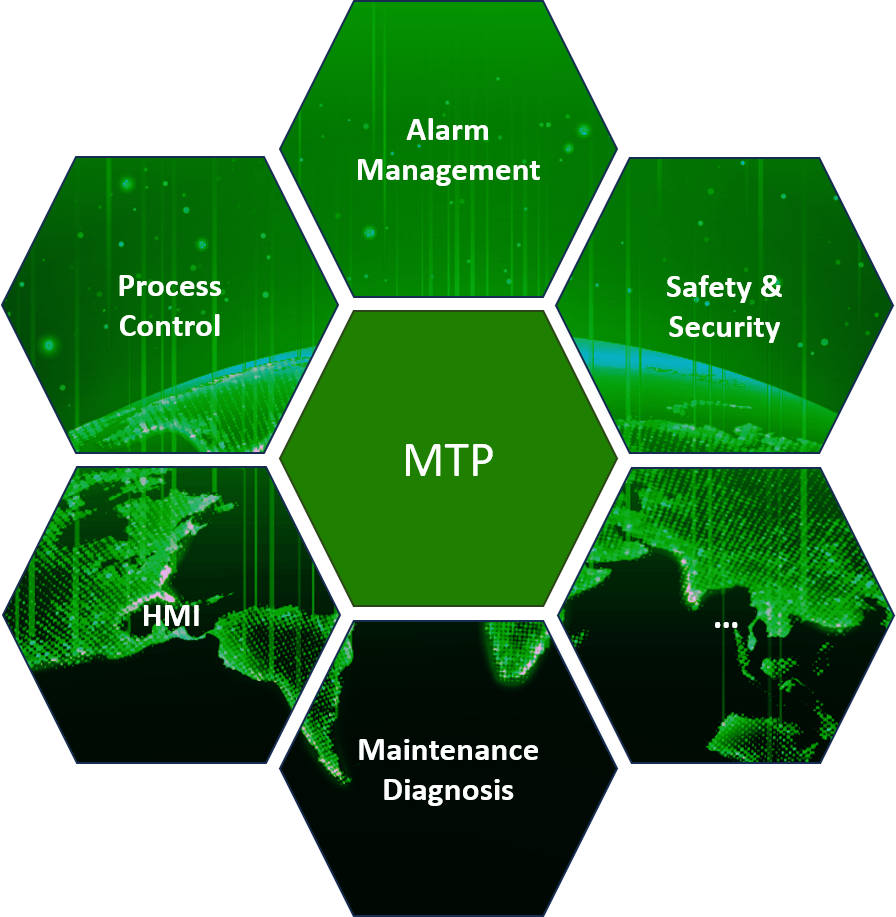

Our highly modular automation solutions offer you unprecedented flexibility for production and research facilities. These modular systems can be flexibly integrated and are equipped with an MTP (Module Type Package) software interface, which enables seamless integration into suitable (POL-capable) process control systems.

MTP is a concept that has become increasingly important in the automation industry in recent years and aims to reduce the complexity of automation systems while improving scalability and ease of maintenance. For example, operating screens or alarm information for the modules are automatically generated in the control system.

MTP uses functional modules that can be easily combined with each other to create customized automation solutions for different applications. Each module is self-contained and has manufacturer-independent interfaces that allow it to be seamlessly integrated into an overall system.

The advantages of Module Type Packages are multifaceted. They enable faster development of automation systems, as prefabricated modules can be used. This saves time and resources during system integration. They also facilitate scalability, as new modules can be added as required. Maintenance and troubleshooting are also simplified as defective modules can be easily identified and replaced.

Customized Automation

We offer you the option of integrating customer-specific automation systems. In this case, automation can be carried out either by third-party providers commissioned by us or by your own company. This may be desired, for example, if you already operate a certified automation system or if you have special requirements that cannot be implemented with our automation solutions.