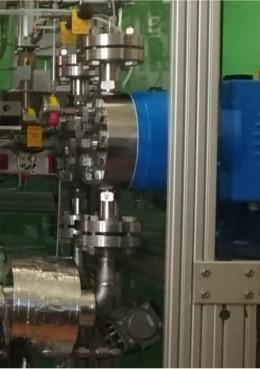

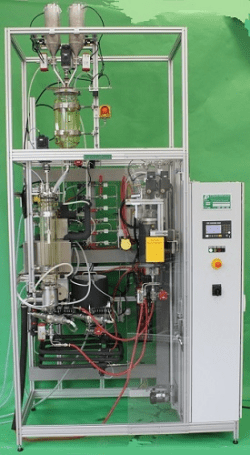

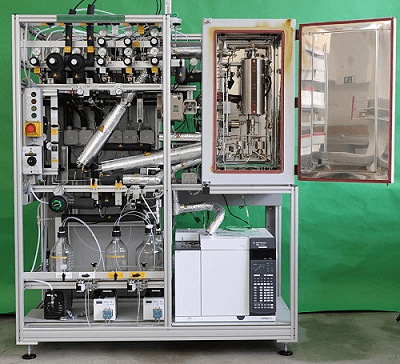

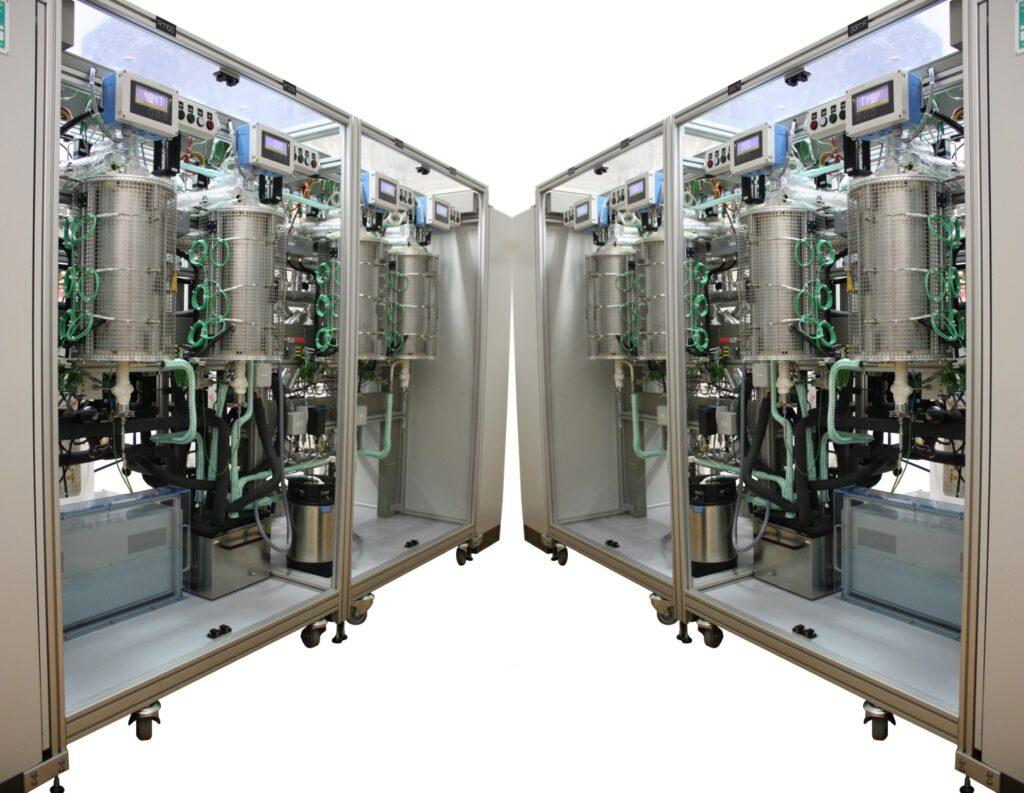

This plant consists of an oscillating bed reactor with a pulsator, offering a versatile platform for various reactions. The reactor consists of 2 adjacent tubes with heating jackets, which are connected to each other via a U-tube. The internals are inserted into the tube and are therefore also variable. Mixing is achieved by a pulsating current generated by a diaphragm pump without pumping function. There are dosing options at various points in the reactor. The system supports gas, liquid, and slurry dosing, providing adaptability to different experimental needs. It features a two-zone temperature control system for precise thermal management.

Interchangeable inserts can be used to determine the optimum conditions for the formation of a stable fluidized bed. The system allows pressures of up to 60 bar and temperatures of up to 200 °C.

Features:

- Oscillating bed reactor with pulsator.

- Gas, liquid and slurry dosing systems.

- 2-zone temperature control.

- Exchangeable inserts.

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 2310 x 990 x 1900 |

| Weight | kg | 1185 |

| Electrical supply | 3P ~ 380 V / 60 Hz / 35 A | |

| Ambient conditions | °C | 10 to 35 |

| Pressure conditions | bar | PS = -1 to 60, recommended max. operation pressure 48 bar |

| Temperature conditions | °C | -10 to 200 |

| Reactor type | OBR Poly-Reactor, 2 l, Pop = 20-48 bar / Top = 60 -190 °C | |

| Other | Pulsator, 4x receiver tanks | |

| Supplies | Gases, liquefied gases, solvents, additives, catalyst, co-catalyst | |

| Heating/cooling | With electrical oil thermostat and with electrical heating jackets |