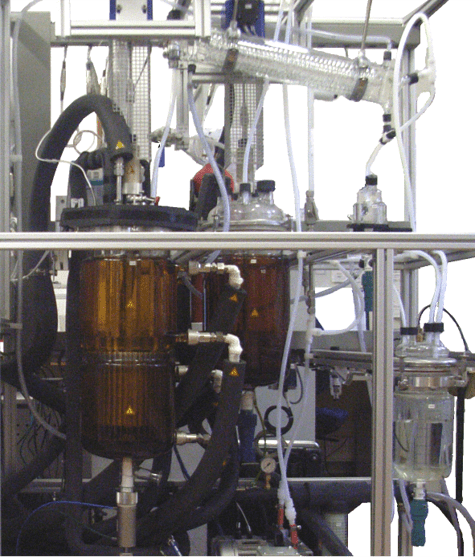

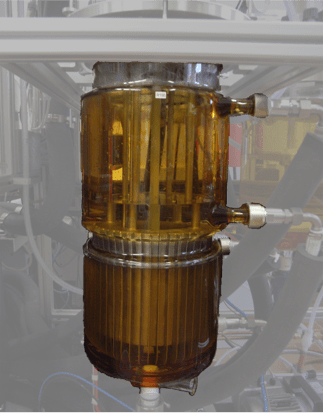

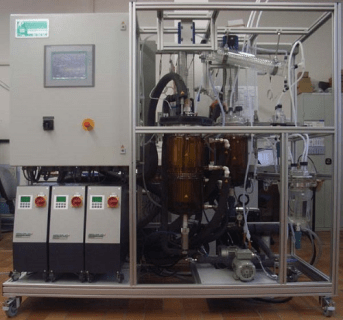

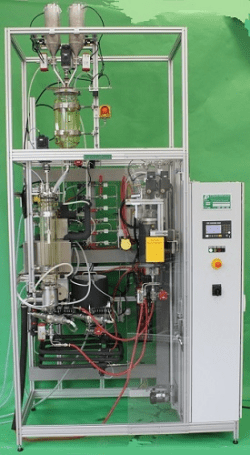

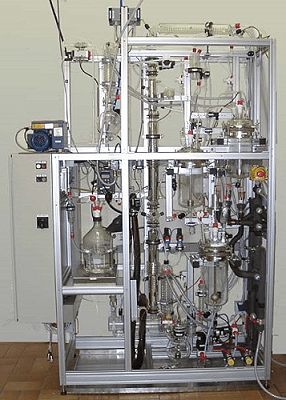

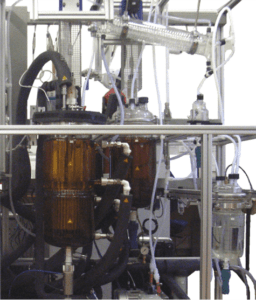

The crystallization plant is designed for the crystallization of solids from a concentrated aqueous solution under vacuum. The feed tank is equipped with a heating jacket and a propeller stirrer. The feed lines to the main reactor vessel are fitted with trace heating. Crystallization takes place in the glass reactor. It is equipped with a heating jacket, which is divided into an upper and a lower part, and a special finned heat exchanger. Both parts are connected to separate thermostats for optimal temperature control. The vaporized liquid is condensed in the glass condenser and collected in up to two different vessels.

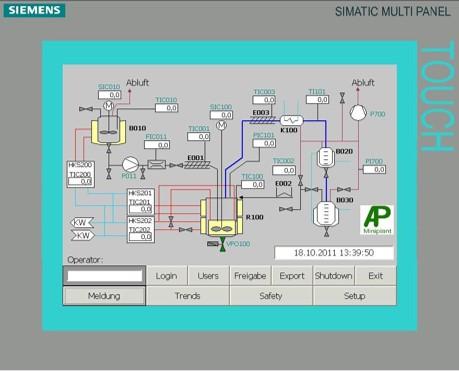

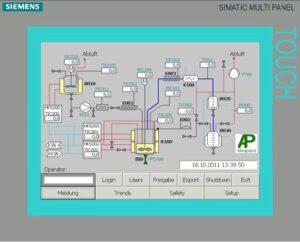

Our crystallization plant can be controlled intuitively via an integrated touch panel. Both the temperature up to 150 °C and the desired system pressure are set via the integrated vacuum pump.

Features:

- 10 L and 15 L stirred reactor.

- Easy operation with touch panel.

- Heating jacket for up to 150 °C.

- Vacuum pressure control.

Technical Specifications

| Description | Unit | Value |

|---|---|---|

| Dimensions L x D x H | mm | 2100 x 800 x 1950 |

| Weight | kg | 480 kg |

| Electrical supply | 400 V AC, 50 Hz, 16 A, 6,4 kW | |

| Reactor volume | L | 10 and 15 L |

| Temperature specifications | °C | Tmax = 150 °C |

| Pressure data | bar | 0 to 1 bar |

| Reactor | Borosilicate glass, stainless steel: 1.4404, 1.4571, AISI 316, 316L, PTFE | |

| Instrument air | bar | 1.5 to 16 bar, min. 3 bar are needed |

| Cooling water needed | 1 to 6 bar, Δpmax= 0.3 bar | |

| Ambient conditions | 5 to 35°C, max. humidity < 80 % |