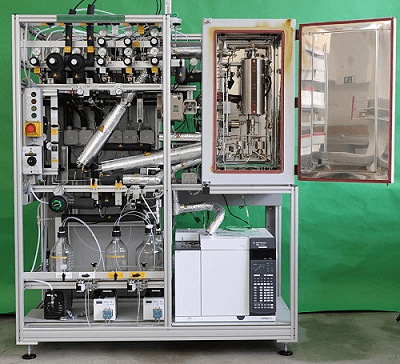

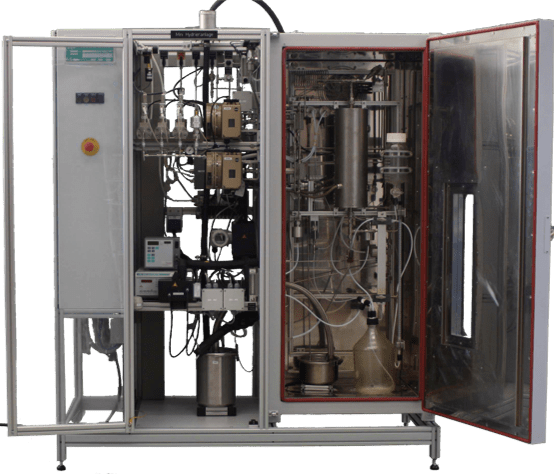

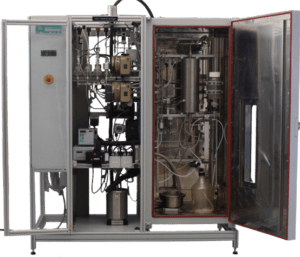

This catalyst test plant for high-melting fluids such as wax comprises a heated convection oven that is purged with inert gas. This ensures the heating and flowability of all components for highly viscous educts or those with a melting point above ambient temperature.

It has a three-zone furnace, which is equipped with a tubular reactor and enables temperatures of up to 550 °C in the reactor chamber. The supply of the various reactants is controlled by heated high pressure pumps, which allow precise dosing of very viscous(or high melting-point) components. The integration of an industrial control system into the catalyst test system facilitates the monitoring and automation of operation and increases safety.

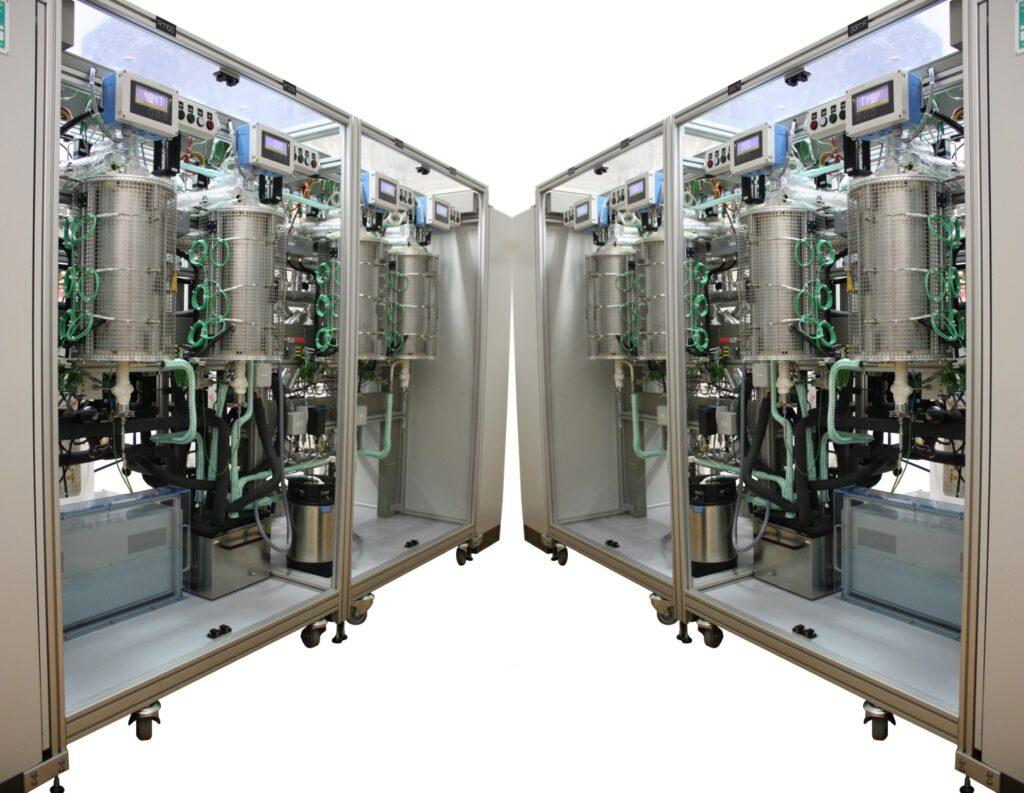

In addition to this catalyst test plant, we offer other systems as part of our AP-SmartPlant product line.

Features:

- Heated convection oven flushed with inert gas.

- 3-zone split furnace with tubular reactor.

- Feed dosing with high pressure pump.

- Industrial control system.

Technical Specifications

| Description | Unit | Value |

|---|---|---|

| Dimensions W x D x H | mm | 1680 x 800 x 1920 |

| Weight | kg | 500 |

| Electrical supply | 3 x N/PE 230/400V AC, 50 Hz, 16A, 6 kW | |

| Convection oven | 2 kW, 148 °C | |

| Temperature specifications | °C | -10 to 350 under pressure, -10 to 550 at ambient pressure |

| Pressure data | bar | -1 to 200 @ temperatures up to 350 °C, recommended max. operating pressure is 160 bar |

| Vertical split furnace | 3 zones, design temperature 950 °C | |

| Reactor type | Tubular stainless steel reactor, DN 15 | |

| Gas supplies | Nitrogen, low pressure: 2-3 bar, high pressure: 160 bar Hydrogen, 160 bar Air, 6 bar | |

| Liquid supplies | Viscous or solid hydrocarbons with melting temperature < 130 °C | |

| Gas / liquid separation | Cyclone with differential pressure sensor for liquid level measuring |