Customized Laboratory Plants and Individual Solutions

Laboratory Plants and Miniplants

With over 25 years of experience in the construction of laboratory plants and miniplants, we help companies and research departments realize their innovations faster and more reliably. We provide design, construction and automation from a single source, ensuring short delivery times and reliable plant engineering.

Industries

Whether you are in the pharmaceutical, chemical, automotive or energy industries or need a plant for another application:

We offer flexible and customised solutions to help you advance your research and development or manufacture smaller product quantities economically.

Companies around the world trust AP-Miniplant for their laboratory-scale systems. Find out more about what we stand for and what our customers say about our plants:

Our Product Lines

AP-MyPlant

Individually planned systems with maximum flexibility

AP-SmartPlant

Preconfigured plants for standard process conditions

AP-LabParts

Special components and parts according to customer requirements

Automation

By default, our plants are equipped with an automation system consisting of hardware controller (PLC) and a PC-based operating and monitoring system.

Depending on the desired degree of automation and system complexity, we distinguish between the following levels:

- Basic automation: For simple systems, single controllers and data recorders in combination with robust control systems offer a particularly cost-effective solution

- Standard automation: For systems with a higher degree of automation, we use Siemens controllers of the S7/1500 series with Profinet connection and Windows PC with the Simatic WinCC SCADA system

- Advanced automation: If the range of functions of the usual automation is not sufficient, we automate your plant with the Simatic PCS7 process control system.

If you want to operate a discontinuous plant, you can easily and conveniently create your own event-driven sequence control with our system. You create this in a user-friendly way in a spreadsheet programme in the form of step definition sheets and thus have full control over each process step.

Measurement data is stored in the system and can be exported to other programs via an export function.

We can also incorporate automation systems according to customer requirements. In this case, however, the automation must be carried out either by third-party suppliers commissioned by us or by our customers themselves.

Learn more about our automation services…

Solutions

We find solutions even for special tasks!

Where possible, we use standard industrial products. This saves costs, simplifies the procurement of spare parts and ensures high reliability.

Sometimes, however, a standard solution is not available. Then you can benefit from our experience and our network of around 700 suppliers. Below you will find some examples of such special solutions.

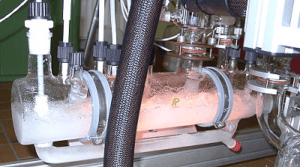

Extreme Process Conditions

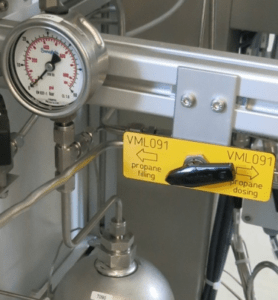

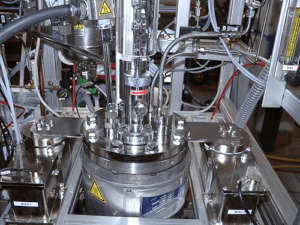

Reliable Cleaning, Filling and Dosing